Extrusion

Boosting Extrusion Productivity-Part II of III: Optimize Product Changeover & Purging

Extrusion processors typically run a number of different products and resins.

Read MoreDryers Use Less Energy to Dry PET

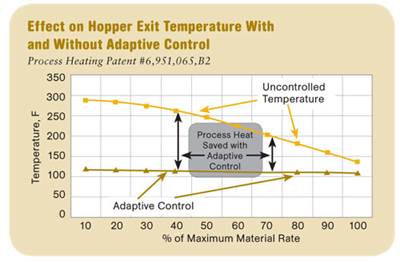

Novatec Inc., Baltimore (novatec.com), is introducing two patented dryer control technologies intended to cut energy costs for processors of PET.

Read MoreSolving the Puzzle of Chinese Bags

How do the Chinese get such high quality at such low cost? They have been accused of dumping, but Chinese bag makers are mostly small mom-and-pop 大象传媒es that survive on razor-thin profit margins. Their plants and the way they run them are like nothing you鈥檝e ever seen.

Read MoreNPE News Wrap-up: Resin Dryers

At least 16 companies introduced new dryers at the big show in Chicago. The new models span a range of drying technologies, but most sport features that save space and cost and make the dryers simpler and more reliable.

Read MoreExtrusion: Take Care of Your Rolls So They Can Play Their Role

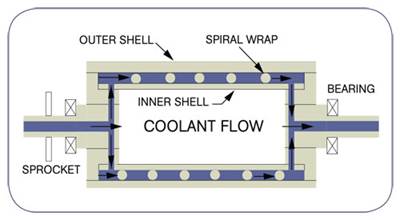

In the sheet extrusion 大象传媒, one of your most important manufacturing assets is your cooling rolls.

Read MoreTooling: The Science of Profile Die Balancing

In our last column, we discussed the five things profile extruders need to know about profile die design鈥攑roper land length, land-length ratio, drawdown, considerations for sensitive materials, and decompression.

Read MoreTests Show Direct-Drive Extruders Are Quieter, More Energy Efficient

Green machines may be coming to extrusion.

Read MoreYour Extruder's Best Friend

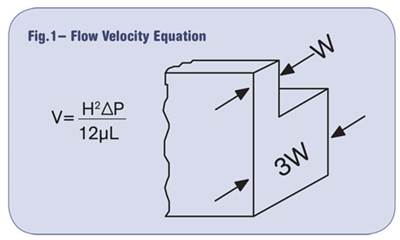

That's the melt pump, and its main purpose is to precisely control output to the die.

Read MoreMaterials at NPE 2003

The footprint of thermoplastic materials suppliers at this year’s NPE is going to be fainter than usual.

Read MoreExtrusion at NPE 2003

NPE is typically a competitive display of the biggest, most dramatic equipment machine builders can muster.

Read More