Extrusion

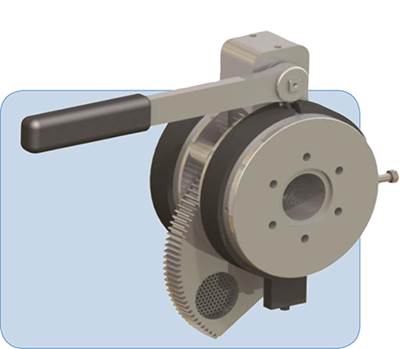

Get Smarter About Melt Filtration

As quality specifications become tighter and the need to use more recycled materials becomes more prominent, more and more extrusion processors are examining their options in melt-filtration technology. Here's some help in evaluating your options.

Read MoreOn Site: Where Art, Science, And Customer Focus Meet

Business strategy at Danafilms involves a mix of art and science in blending resins, designing layer structures, and operating flexibility for both short and long runs.

Read MorePipe Maker Gains Flexibility with Ultrasonic Control System

The recent addition of an ultrasonic gauging and control system is credited by pipe extruder Charter Plastics Inc., Titusville, Pa., with increasing its production flexibility.

Read More'Dryer-less' PET Sheet System

Processing Technologies International (PTi), recently took the wraps off its “dryer-less” twin-screw PET sheet extrusion system at its headquarters in Aurora, Ill.

Read MoreAdd a Layer of COC to Boost Polyolefin Film Properties

As a discrete layer in coextruded polyolefin film, cyclic olefin copolymer provides higher modulus, greater heat resistance, improved thermoformability, and increased barrier

Read MoreHow Fillers Impact Extrusion Processing

Their addition can significantly change the processing properties of a polymer.

Read MoreCentral or Portable? ‘Off-the-Floor’ Central Chillers Cost Less, Provide Processing Gains

In deciding whether to use portable or central chillers, there are a variety of variables to consider. Here are the key issues.

Read MoreCentral or Portable? Flexibility Favors ‘Discrete’ Chillers

Why might discrete chillers be a solution in your plant? In a word: Flexibility. Here is the lowdown.

Read MoreSoak Time and Plate Out Best Practices

What is the ideal soak time for a cold start up of an extruder, especially if there's material in the die and what kinds of resins can lead to plate out?

Read MoreBenchmark Your Extruders For Quicker Processing Fixes

Not recognizing output reductions and resolving them quickly can cost a lot of money. Benchmarking your machines will help.

Read More