best practices

MEDICAL MOLDING: Configure Your Molding Machine Into a ‘Clean Room’

You can meet the stringent requirements of the medical market without having to invest in a full-blown production clean room.

Read MoreMold-Heating/Cooling Technology Keeps Cosmetic Parts Looking ‘Hot’

New rapid mold-temperature control technology allows molder to eliminate cosmetic defects like knit lines or sink marks in parts that require a glossy finish or feature texturing.

Read MoreTeel Plastics: Where Science, Tech, Quality and Innovation Meet

This family-owned custom profile and tubing 大象传媒 controls its own destiny by controlling, well, everything.

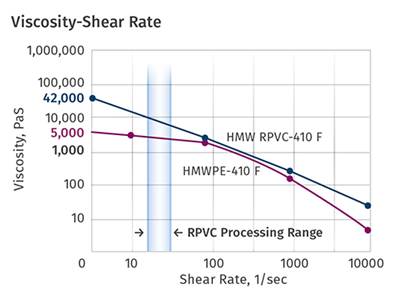

Read MoreEXTRUSION: Processing Rigid PVC? Know Your Rheology

Before choosing and sizing extruders for running rigid vinyl, it is wise to bone up on the viscosity behavior of the material.

Read MoreMATERIALS: Performance in Polyethylene: Density Matters: Part II

Remembering the case of the failed gas tanks.

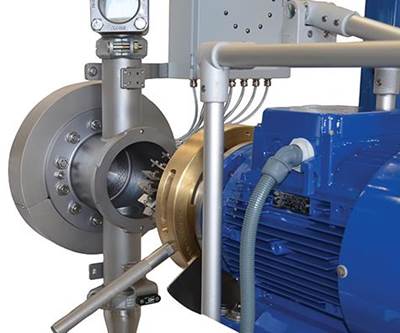

Read MoreSolving Common Problems in Underwater Pelletizing

Pellet quality and consistency are critical to any compounding operation. But in underwater pelletizing, a variety of issues can stand in the way. Here’s how to fix them.

Read MoreResin Conveying: No More ‘Spaghetti Bowl’

You now have technology choices to avoid the maze of conveying tubes that form a ‘spaghetti bowl’ or ‘rat’s nest’ in a central materials-handling system. Here’s how they stack up.

Read MoreWinzeler Gear Thrives With a Little Help from Its Friends

Strategic partnerships give a small molder the technical clout of a much bigger firm.

Read MoreThermoformer’s Name Change Reflects Refocused Strategy

New identity highlights processor’s focus on technology, product quality, and food safety.

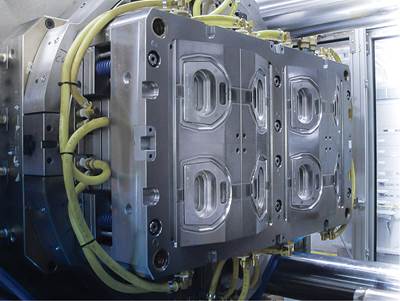

Read MoreTOOLING: Balancing the Heat Budget In Injection Molds

Basic formulas for how much heat you must pull out of the mold to achieve a set cycle time

Read More