best practices

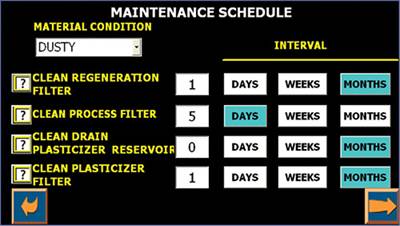

Savvy Processors Reveal Best Practices on Drying

The processors speak: Here’s how some smart molders and extruders tackle the vexing problem of resin drying.

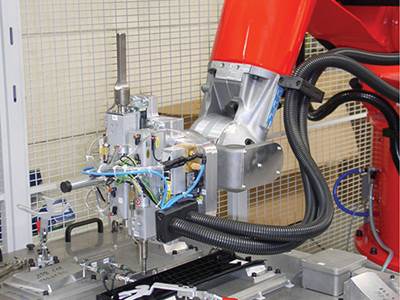

Read MoreHow Pre-Loaded Ultrasonic Welders Save Time in Automated Assembly

Pre-loaded assembly systems mounted on a robot arm are a relatively new, time-saving concept in ultrasonic welding that maintains precision and process repeatability.

Read MoreGranulate or Shred: Which Makes Sense for You?

That is the size-reduction question confronting many processors today. Look here for some guidance.

Read MoreUnderstanding Your Options In Multi-Axis Robots For Injection Molding

With so many choices available today, it’s important for molders to understand the pros and cons of Cartesian vs. articulated-arm robots and how their capabilities overlap more than ever before.

Read MoreBlow Molder’s Goal: Go Local on a National Scale

It's a rare feat: Combining three formerly separate blow molders under one umbrella while retaining their individual identities and "small company feel" for customers.

Read MoreAutomation Pays for Itself At Port Erie

Four dozen robots have helped this molder realize a variety of efficiencies.

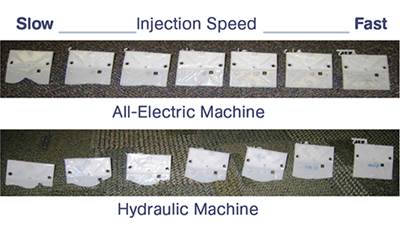

Read MoreINJECTION MOLDING: ‘Know Your Machine’

Many molders think they “know their machine,” but in reality do not. They get consumed by the demands of day-to-day production requirements and lose sight of the big picture.

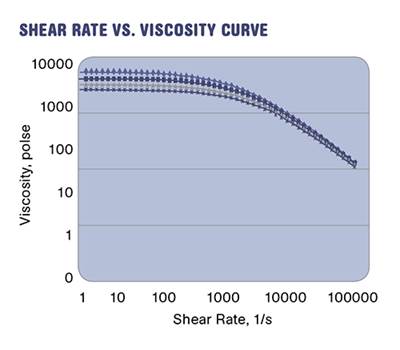

Read MoreMATERIALS: Melt Flow Rate Testing—Part 10

Two areas where the melt flow rate test it is not useful are related to processing.

Read MoreEXTRUSION: Effect of the Screw Flight On Melt Temperature, Energy Use

So-called rules of thumb regarding the design of flight clearance and width do not consider the temperature effect, both from the point of view of melt temperature and energy efficiency.

Read MoreCustom Structural Foam: A Small But Thriving Niche

How to succeed in the small but busy world of custom structural foam? Maximize your pounds per hour and use robots.

Read More