best practices

A Better Way to Balance Die Flow

Use temperature adjustments before making any mechanical tweaks.

Read MoreScrew Speed Versus Recovery Time

Many molders don't take screw-rotation speed into account when developing a process for a new mold. Here's why they should.

Read MoreCompounding PLA on Twin-Screws: What Testing Reveals

Twin-screw extrusion is the preferred method for compounding PLA and other biopolymers. But processing PLA is complicated because it’s sensitive to heat and shear. It’s also prone to hydrolytic degradation if moisture is present in molten PLA. Here’s what one machine builder’s trials revealed.

Read MoreBack to Its Roots in Film Extrusion

After drydocking its film extrusion 大象传媒 in '99, converter goes back to its roots with upstart sister company.

Read MoreThe Power of Numbers: Time to Step Up to Five Layers

Five-layer technology can provide processors with more productivity and greater flexibility to produce a wider range of products from a single line.

Read MoreThe ‘Total Package’ in Thermoforming

Here's how a leading edge custom former evolved from a CAD/CAM 大象传媒.

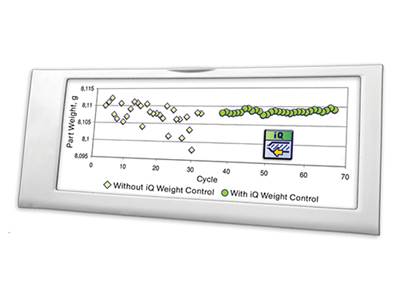

Read MoreSwitch Over To Consistent Quality

A new process-control method picks up variations in melt quality and viscosity during the injection phase and equalizes them within the same shot.

Read MoreFive-Layer Line Gives Processor More Flexibility, New Opportunities

Processor bumps it up from three-layers to boost quality, flexibility and enter new markets.

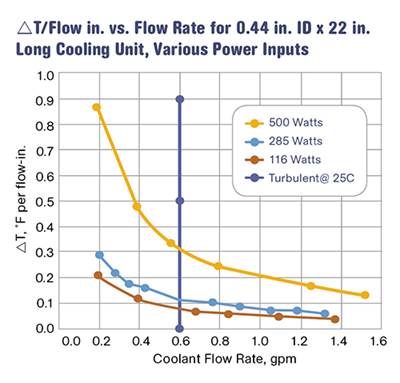

Read MoreLeverage Your Cooling Power

You can predict the amount of heat you'll need to remove from parts before ejection with reasonable accuracy if you know polymer thermal properties and certain other rules of thumb.

Read More