best practices

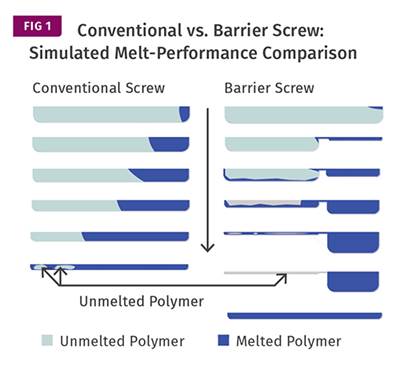

Understanding Solids-Bed Breakup in Barrier Screws

Barrier screws all but eliminate problems associated with solids-bed breakup. But if they do occur, tremendous pressures can develop, causing screw wear.

Read MoreHigh-Pressure Water: A New Concept for Screw Cleaning

Everyone in a molding plant is on the same page for screw cleaning: Avoid pulling it until there is no alternative. Here are ways for dealing with the inevitable, including an altogether new technique.

Read MoreThe Mystery of Physical Aging, Part 2: Slow Down Aging

Dimensional and property changes depend on the size of the part, molecular weight of the resin, and processing conditions.

Read MoreYour Options for Mold Venting

When should you use machined vents or porous, sintered metals? Here are some guidelines.

Read MoreHow Currier Puts the ‘Custom’ In Custom Blow Molding

The three key ingredients are responsiveness, full-service product development, and control over both the bottle and the cap.

Read MoreOptimizing Thin-Gauge Sheet for In-Line Thermoforming

Processing thin-gauge sheet for in-line thermoforming poses unique challenges. Here’s how to cope with them.

Read MoreColor Compounder Enters Market with a Bang

To get noticed in the color masterbatch 大象传媒—particularly in white—you’ve got to start big. That, and new technology, form the foundation for startup Neko Colors

Read MoreTOOLING: Flash-Free Molding: Part Two

Parting-line maintenance, mold spotting, and machine conditions can all contribute to flash.

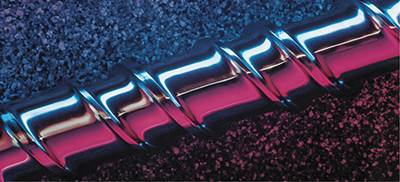

Read MoreEXTRUSION: Why Bother to Chrome Plate Your Screws?

It doesn’t add that much to the overall cost and can improve performance and facilitate maintenance. So the better question is: Why not?

Read MoreINJECTION MOLDING: How to Tell If Your Non-Return Valve Is Leaking

Check valves are potentially troublesome devices. Here’s how to find out if yours is behaving properly.

Read More