best practices

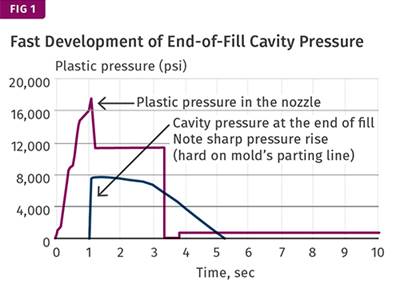

INJECTION: First to Second Stage Transfer: Should There Be ‘Bounce-Back’?

How much screw ‘jumping’ or bounce-back can your process tolerate? The answer is no surprise: It depends

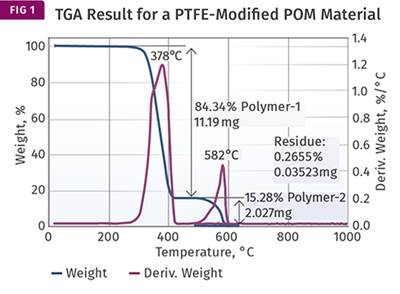

Read MoreMATERIALS: Analysis Gone Wrong

A lot of resources are devoted each year to trying to figure out why products fail. Sometimes it’s because no one involved in a project realizes the data provided was wrong.

Read MoreHow to Split & Clean Flat Dies

Notice a drop-off in quality of your flat film or sheet? It may signal that a die ‘split-and-clean’ is due. Here’s how to get going.

WatchMolder Strives to Align People, Processes, Technology

Wisconsin Plastics’ ‘transformation’ takes into account all aspects of its 大象传媒, with the help of its machinery sales rep.

Read MoreBOPP Processor Focuses on Specialties

At one time, BI-AX International produced millions of pounds of BOPP film a year for a wide range of commodity products. But it has since transitioned toward higher-value niche products for medical and packaging.

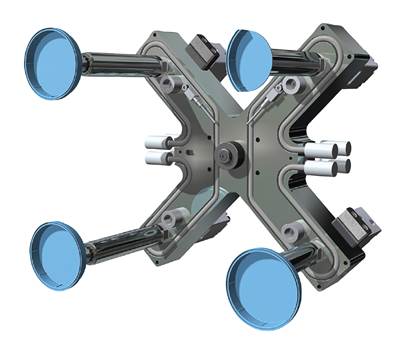

Read MoreFixing Hot-Runner Filling Imbalances: Take a Systematic Approach

Jumping right in to try to make a fix without a methodical troubleshooting approach is apt to waste a lot of time and perhaps even make things worse. There is a better way.

Read MorePut the Brakes on Resin Conveying Speed to Minimize System Maintenance

Here’s how to manage pneumatic conveying speeds to extend equipment life and reduce material waste in your plant.

Read MoreTOOLING: Designing the Tool for the Material

To design a mold for the widest processing window and the fewest problems, start by considering the conditions imposed by the material being run.

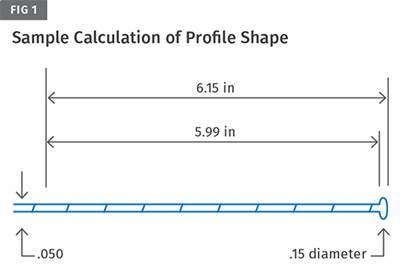

Read MoreEXTRUSION: About Your ‘General-Purpose’ Dies

There is no such thing. While dies can be adjusted to provide some flexibility, the fact is they are optimized for one specific output of one particular polymer.

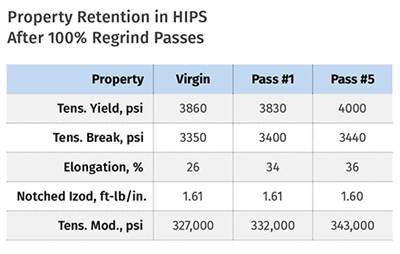

Read MoreINJECTION MOLDING: Another Way to Deal with Regrind

You can run into a lot of problems molding parts from a blend of regrind and virgin material. Might you be better off using 100% regrind?

Read More