best practices

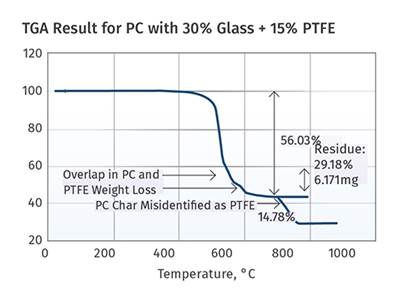

MATERIALS: Analysis Gone Wrong: Part 2

But even misinterpreted tests can yield an approximation of the real composition of the material.

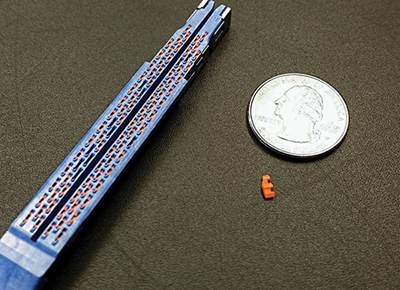

Read MoreMicromolding Gets Bigger at Tessy Plastics

Micro parts are a tiny but fast-growing segment of its custom molding 大象传媒, with potential to expand beyond the medical sector.

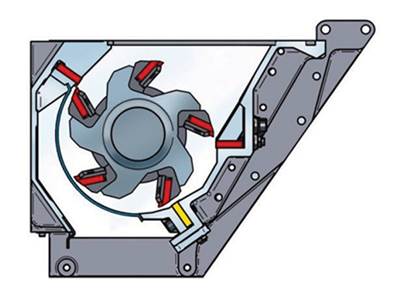

Read MoreEnergy-Efficient Granulating

Granulators are notorious energy hogs, but motors and designs have improved energy efficiency over the years. Proper selection and maintenance can also do a lot to avoid wasted energy cost.

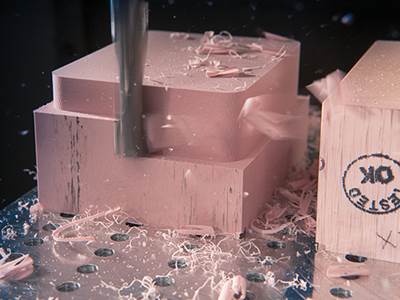

Read MoreFive Steps Toward Better Plug Assists

With careful planning and adherence to best practices, crafting the right plug assist can put you on the path to high-quality, repeatable parts.

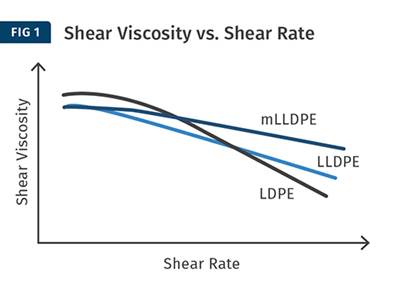

Read MoreCoextruding Blown Film Needs Deeper Understanding of Resin Rheology & Die Design

More film processors are investing in lines with nine or more layers. With more resin possibilities and combinations coming into play, it’s important to learn more about material rheology and compatibility, as well as die design.

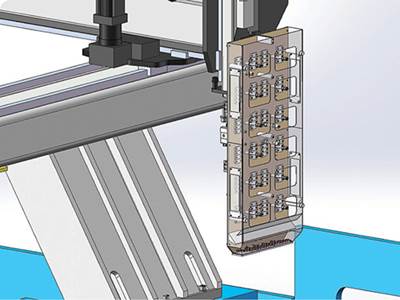

Read MoreRobot End-of-Arm Tooling: Making a Big Difference

Often overlooked as a small part of an automation system, clever end-of-arm tooling techniques and designs can improve part quality, heighten efficiency, and eliminate headaches for any molder.

Read MoreMolder’s Mantra: Go Lean, Stay Green

All-electric presses combined with home-built technologies and energy-efficient initiatives at PMT.

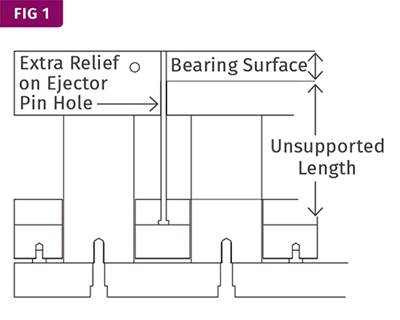

Read MoreTOOLING: Ejectors: Watch That ‘Unsupported Length’

It may be an unfamiliar term, but it’s the key to preventing ejector-pin deflection and breakage

Read MoreBLOW MOLDING: Single- or Two-Stage PET Bottle Making: Get to Know Your Options

The decision which process to use can be quite complex. Here are pointers that will help you to choose the right one for your application

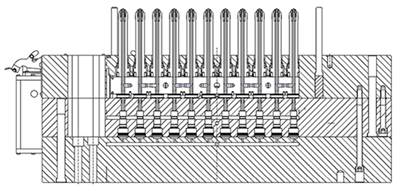

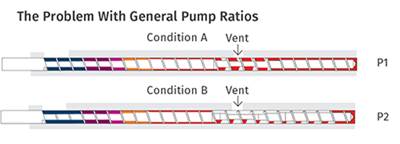

Read MoreEXTRUSION: Avoid General ‘Pump Ratios’ On Two-Stage Screws

Instead, rely on basic data and calculations to determine the proper depth of the first and second metering sections

Read More