best practices

Extrusion: How to Adjust for Polymer Shrinkage and Orientation

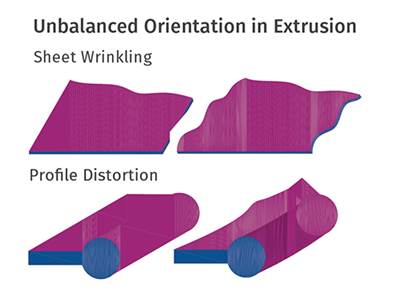

Polymers shrink and orient. Sometimes orientation is unbalanced, resulting in misshaped parts. But there are steps beyond tweaking the die that can mitigate these effects.

Read MoreINJECTION MOLDING: How to Specify an Injection Molding Machine

There are 51 things to consider when spec’ing a controller.

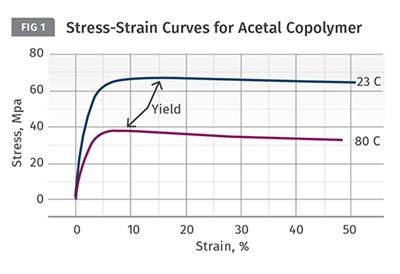

Read MoreMATERIALS: The Problems With Single-Point Data

Polymer properties are not constant as a function of temperature, and even small temperature changes can affect properties.

Read MoreFrom Extruder to Pelletizer: What Happens in Between Influences Quality

There’s a lot more to strand pelletizing than dunking material in water and hoping for the best. Here’s some advice on taking out some of the guesswork.

Read MoreTroubleshooting Material Burning In Hot-Runner Systems

Burns in hot runners can be misleading and hard to diagnose correctly. Follow these tips to track down the root cause of your problem.

Read MoreOn-Site: A Big Molder’s Technical Engineering Plus a Small Company’s Customer Service

That’s the formula for rapid growth at a new/old firm serving medical, military, and aviation markets.

Read MoreAir-Ring Upgrades Get Film Processor Quickly Up to Spec

PolyExpert’s trials lead to installation of three new air rings and one digital IBC control to speed changeovers and reduce scrap.

Read MoreTOOLING: How to Vent Mold Details

Principles to follow in venting bosses, ribs, pins, cores, slides, and lifters.

Read MoreEXTRUSION: Another Technique for Controlling Melt Temperature

Flight widths are almost always designed at 10% of the screw diameter. But they can be optimized to reduce melt temperature and perhaps boost output.

Read MoreINJECTION MOLDING: How to Specify an Injection Molding Machine

In part two of a three-part series, the focus is on the injection unit.

Read More