best practices

15 Things to Know About Servo-Driven Injection Machines

Drive technology for injection molding machines has been continuously evolving, and servo motors have become widely used in a variety of roles. Here’s what molders need to know about today’s servo drives in terms of cost, performance, maintenance, and training.

Read MoreHow to Collect and Interpret Process Data in Extrusion: Part 2

In this second of three installments, the focus is on the crucial element of melt temperature.

Read MoreWorld-Class Processors: Meet Plastics' Preeminent Processors

Plastics Technology’s second annual benchmarking survey is back with a new honor roll of companies from across the industry. One of the ties that binds these progressive processors is their reliance on data.

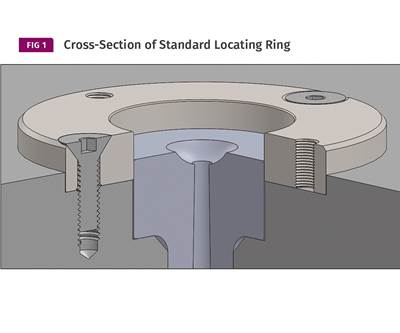

Read MoreWhat You Need to Know About Locating Rings: Part 1

Selecting the right locating ring and putting it to good use takes a lot of thought.

Read MoreExtruding with Fillers

You can use the reference point from processing unfilled polymer to determine whether you can run filled resin on your current system.

Read MoreEnergy Consumption Made Visible

Molder adds system that allows it to track energy usage in nearly real time and is now using less power, despite increased production.

Read MoreExtrusion Powerhouse Does It All

Tekni-Plex has evolved into a technically diverse global supplier of a wide range of extrusions for a host of markets, many of which are regulated.

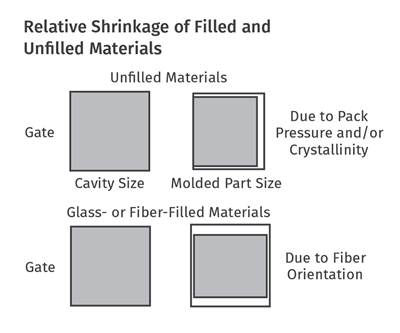

Read MoreHitting the Numbers, Part 2: The Shrinkage Factor

The shrinkage factor is one of the most critical numbers to hit.

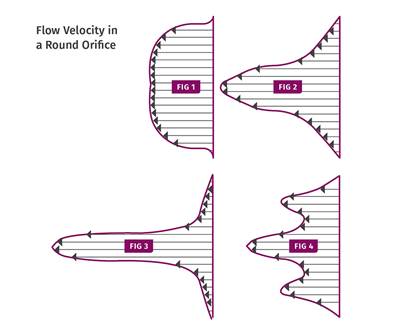

Read MoreDon’t Build In Melt-Temperature Variations

It’s not unusual for polymer to exit the extruder with a uniform melt temperature, only to be fouled up by downstream flow pipes and the like. Here’s how to avoid this.

Read MoreThe Need for Generalists, Part 2

Problem-solving requires a team that combines people having academic credentials with others who have hands-on experience.

Read More