best practices

Materials: Cycle Time: Science vs. Rules of Thumb—Part 2

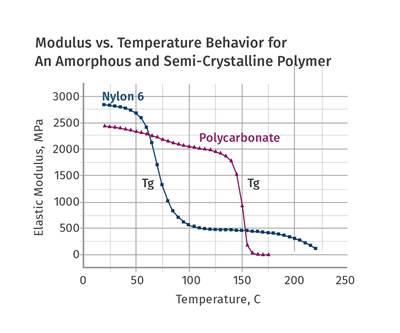

Understanding cooling—how a given material develops modulus as it solidifies—requires access to data that provides some insight into the relationship between modulus and temperature. Dynamic mechanical analysis is a helpful tool.

Read MoreUnderstanding Low-Rate Feeding for Continuous and Batch Processes

Molders and extruders that need to feed tiny amounts of material to their process require precision in both the material being fed and the equipment doing the dosing. When a shot size consists of three pellets, there is no margin for error.

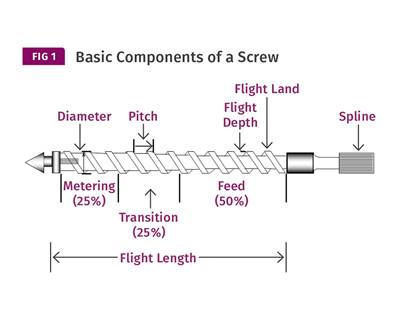

Read MoreHow to Collect and Interpret Extrusion Process Data; Part 3

In this final installment, learn how process data can be used to identify and fix extrusion issues.

Read MoreMedical Molder Sweats the Small Stuff to Deliver Big Results

Embracing lean manufacturing and scientific molding keeps Freudenberg Medical on top of customer demands for defect-free deliveries as it expands into full device manufacturing, 100% automated inspection, and 3D-printed tooling for quicker product launches.

Read MoreTooling: Reducing the Mass In Sprue Bushings

Important and frequently overlooked details of sprue-bushing design can improve the process and profits for an injection mold.

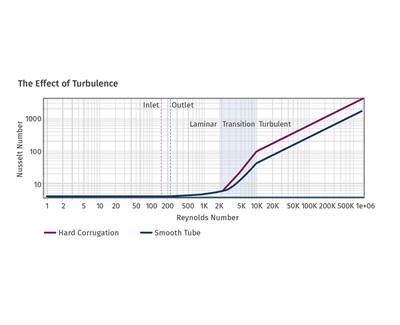

Read MoreExtrusion Cooling: It’s All About Turbulence

Regardless of what you are extruding, in order to maximize cooling you need to generate turbulence at the heat-exchange surface.

Read MoreInjection Molding: Are You Using More Than 65% Of Your Barrel Capacity?

If you are, you are inviting Murphy—as in trouble—to the party.

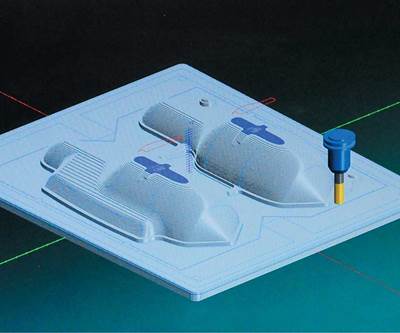

Read MoreCAM Adds Agility to Custom Thermoformer

CNC machining permeates ATI’s 大象传媒, making its operations more efficient and responsive.

Read MoreHow to Solve Common Ultrasonic Welding Problems

Understand and address the likely origins of welding problems to keep production on track.

Read MoreMedical-Tubing Innovator Bets on Silicone Solutions

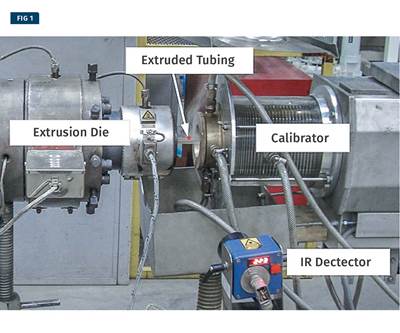

Trelleborg gains footprint in silicone-based implantable medical extrusions.

Read More