best practices

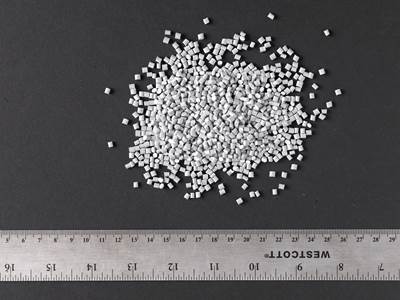

Medical Molder Cuts Resin Dust to Boost Quality & Output

As a result, part yields are boosted from only 3% to 60% or more.

Read MoreTo Produce Quality Extrusions, Get Control Over Melt Temperature

Temperature zone settings are often misunderstood and improperly adjusted. This often contributes to poor film quality and lower production.

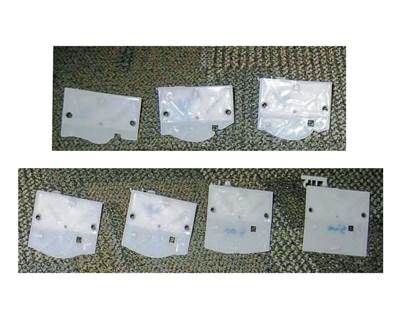

Read MoreHow to Prevent Stress Whitening in PP Copolymers

A look at causes, detection, and prevention.

Read MorePutting Industry 4.0 to Work in a Molding Plant

Learn why—and how—innovative molders have begun to develop “smart factories,” using advanced equipment, IT, and communication technology to enable greater connectivity and productivity.

Read MoreSuccess Through Process Diversity

From heavy-gauge to light, and from the medical industry to the transportation market, Brentwood utilizes its wide range of thermoforming capabilities and expertise to engage customers around the world.

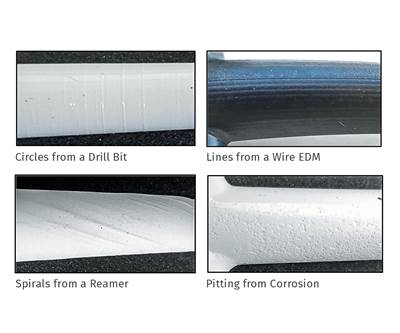

Read MoreTooling: Dealing with Sprue Bushings On the Production Floor

Causes of and solutions to some problems you probably deal with every day.

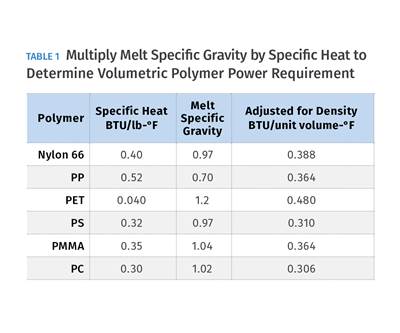

Read MoreExtrusion: The Role of Polymer Density in Screw Design

Density affects the mass flow rate, and energy transfer is based on mass, not volume. As a result, polymer density enters into practically every calculation in a screw design.

Read MoreInjection Molding: DOEs Done Right

Doing DOEs for the sake of doing them wastes time and money. But they can provide vital information to determine which process variable is determining a critical part characteristic.

Read MoreCycle Time: Science vs. Rules of Thumb—Part 4

While laboratory tests are helpful in determining how polymers behave, you must remember the fundamental differences between laboratory measurements and the real world of plastic processing. Let’s examine semi-crystalline polymers here.

Read MoreInjection Molding: How Repeatable is Repeatability?

Process repeatability is not a constant, but varies over time in response to a number of variables. That variation is not captured by a snapshot in time—measuring a discrete sample of parts. And the only way to manage that variation is with process controls that adjust each and every cycle.

Read More