best practices

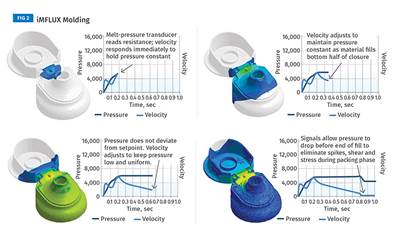

A New Way to Mold Better Parts Faster and Easier

A new injection molding process ‘breaks all the rules’ by using low, constant pressure to achieve faster cycles and better-quality parts.

Read MoreTechnology Is the Solution For This Compounder

Compounding Solutions has seen its 大象传媒 grow by 20% in each of the last 12 years. That’s no accident. The firm has become a mainstay supplier of compounds—primarily for medical—by tapping into its expertise in technology and processing.

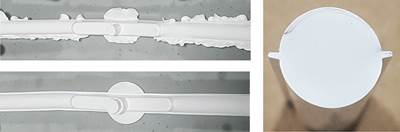

Read MoreTooling: Hot Sprues—Mold a Disk or Not?

Having a hot sprue shut off against the parting line versus intentionally molding a thin disk has been the subject of controversy for many years.

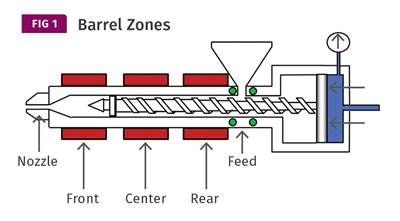

Read MoreInjection Molding: How to Set Barrel Zone Temps

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreA Processor’s Most Important Job, Part 3: Unintended Consequences

Processors are often expected to compensate for ill-advised decisions made earlier in the product-development process. In the case of shrinkage, one of the most common ‘fixes’ is to simply reduce the mold temperature.

Read MoreWhat is Your Extruder Trying to Tell You?

Being in tune with your film extrusion equipment will allow you to identify issues before they start impacting production.

Read MoreFollow These Tips to Power Up Your Purging Process

A properly executed purging process can save processors thousands a year in lost production while helping them increase output and avoid scrap. Here’s how to optimize your results.

Read MoreTooling: Tunnel Gates for Processors, Part 2

What you need to know to overcome problems out on the production floor.

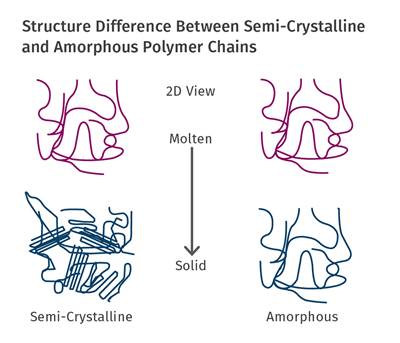

Read MoreInjection Molding: Melting Amorphous vs. Semi-Crystalline Plastics

Understanding the differences in how each melts is crucial to obtaining melt uniformity.

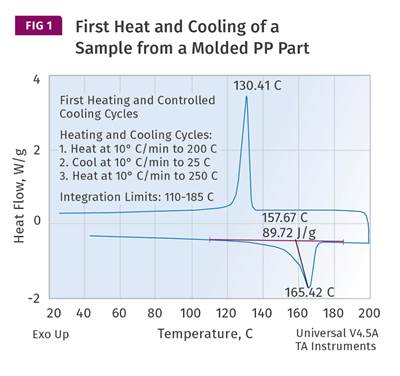

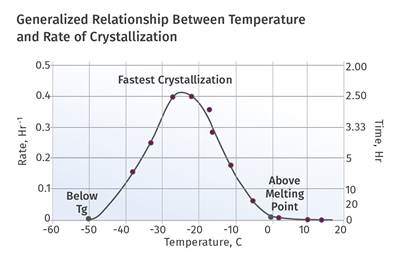

Read MoreA Processor’s Most Important Job, Part 2: Crystallinity

Process conditions help determine the difference between the maximum degree of crystallinity that can be achieved in a polymer and the degree that is present in a molded part.

Read More