best practices

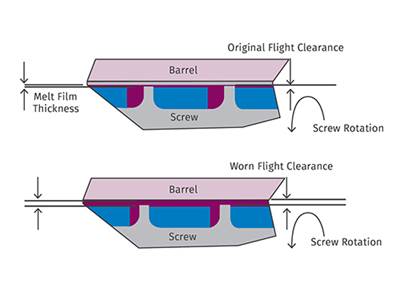

Do You Have Screw Wear?

It’s generally caused by metal-to-metal contact, and your first indicator will be poor melt quality.

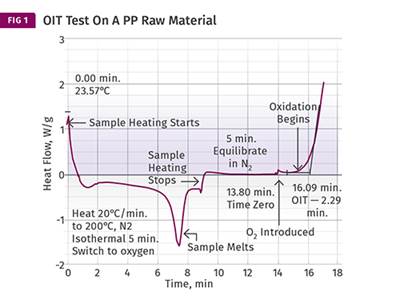

Read MoreThe Importance of Oxidative Stability In Polyolefins, Part 2

The DSC test can do a reasonably good job of capturing the comparative behavior of materials that use similar antioxidant chemistries.

Read MoreAvoid These Three Mistakes to Get the Most from Color

Here are the key misconceptions and common practices that keep processors from reaching the heights of coloring proficiency. Find out if you’re stumbling into these pitfalls, and learn how and why you should swerve around them

Read MoreFive Effective Ways to Control Color

A 50-year veteran in color-concentrate production and use shares practices to help you make better color decisions and generate less scrap. To specify color correctly and communicate your specs to your color supplier requires understanding of the “Five U’s.”

Read MoreWhat You Should Know About Molding Wood-Plastic Composites

Originally targeted mainly for extrusion, new options for wood-plastic composites have been optimized to open doors for injection molding applications.

Read MoreProfile Extruder Sees the Light

Rotuba exited the sheet 大象传媒 to focus on custom profiles for LED light fixtures. It now ranks as North America’s leading profile extruder in this burgeoning market.

Read MoreEXTRUSION: Is Head Pressure Sapping Your Extruder’s Strength?

A redesign of all of the flow paths between the end of the barrel and die may be in order.

Read MoreINJECTION MOLDING: How to Mold Living Hinges With No Flexing Required

Here are the five critical, intertwined components that must be perfected for a living hinge that doesn’t need to be flexed upon ejection.

Read More