Tooling

Check Out the New PTonline.com

Following the relaunch of our print publication and electronic newsletters, our website has a new, vibrant look now, too.

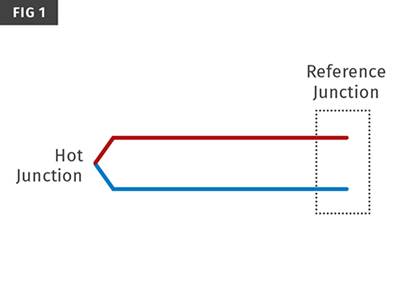

Read MorePrevent & Minimize Downtime in Hot Runner Molding

There are simple explanations for the most common hot-runner problems and equally simple ways to prevent them. One is to take advantage of features often overlooked in today’s hot-runner controls.

Read MoreTOOLING: Flash-Free Molding: Part 1

A robust process window relies a lot on tooling. So it stands to reason that making a tool change to address issues provides a more robust solution

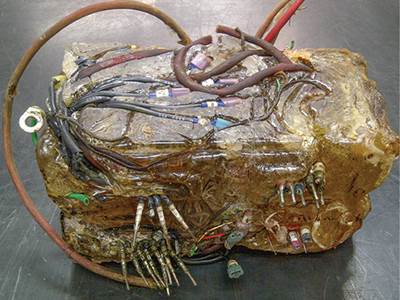

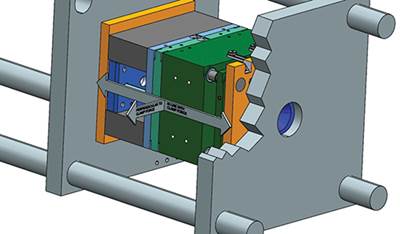

Read More3D Printing of “Porous” Tools Awarded Walmart Research Grant

What if you could build a tool that had just the right amount of material it needed in just the right places?

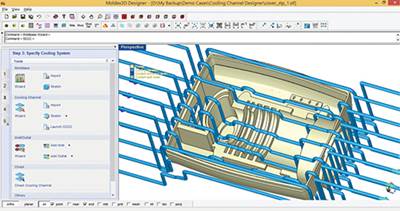

Read MoreINJECTION MOLDING: Mold Simulation Software Gains Speed and New Functionality

It's faster, easier to use, and supports more sophisticated modeling.

Read MoreReduce Hot-Runner Downtime With Proper Troubleshooting

Solve your problem faster by adopting a systematic approach. Here’s how to get going.

Read MoreB&B Molders Sticks to Its Core— Core Values & Core Competencies

To compete in today’s market, you need good technology, but you also need to know what you stand for and what you’re good at.

Read MoreWhat Processors Are Doing To Bridge the Skills Gap

Seasoned technicians are leaving, and replacing them with youngsters is a challenge. But some processors have taken dramatic initiatives to change how young people think about manufacturing and are bringing the next generation into the fold.

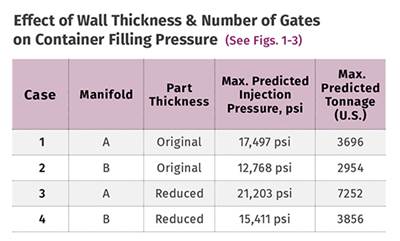

Read MoreINJECTION MOLDING: The Importance of Nominal Wall For Lightweighting Molded Parts

Establishing a nominal wall is one of the most important decisions an engineer makes when designing parts. Understanding how design changes will impact the manufacturing process is critical to ensure the part performs as expected.

Read MoreFEA Software Predicts Material Response to Repeated Snap Fits

Improved finite-element modeling accounts for viscoelastic response to multiple stress-strain cycles.

Read More