Tooling

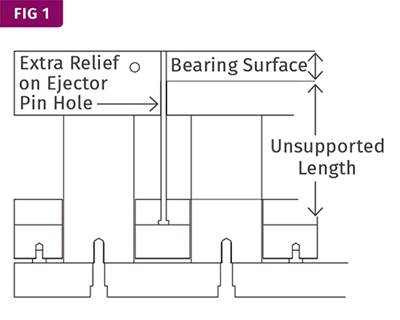

TOOLING: Ejectors: Watch That ‘Unsupported Length’

It may be an unfamiliar term, but it’s the key to preventing ejector-pin deflection and breakage

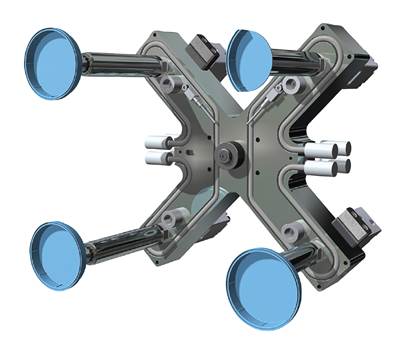

Read MoreBLOW MOLDING: Single- or Two-Stage PET Bottle Making: Get to Know Your Options

The decision which process to use can be quite complex. Here are pointers that will help you to choose the right one for your application

Read MoreNews in Hot Runners & Tooling At Fakuma 2014

Novelties included variable-pitch manifolds, mold servo controls, 3D printed plastic mold inserts, and flexible/formable cooling channels.

Read MoreFixing Hot-Runner Filling Imbalances: Take a Systematic Approach

Jumping right in to try to make a fix without a methodical troubleshooting approach is apt to waste a lot of time and perhaps even make things worse. There is a better way.

Read MorePlastics Processors Planning Equipment Spending Spree

Gardner鈥檚 latest survey indicates a robust 17% increase in capital equipment purchases planned for in 2015. What does this mean to you?

Read MoreTOOLING: Designing the Tool for the Material

To design a mold for the widest processing window and the fewest problems, start by considering the conditions imposed by the material being run.

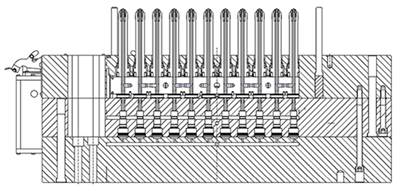

Read MoreHow to Mold Long Fiber Reinforced Thermoplastics

Here’s the machinery, tooling, and process know how you need to get the most out of these high-performance materials.

Read MoreThe Importance of Gate Geometry

Gate size and shape—unlike gate location—don’t often get the attention they deserve. Many common assumptions about gate geometry deserve to be challenged

Read MoreYour Options for Mold Venting

When should you use machined vents or porous, sintered metals? Here are some guidelines.

Read MoreTOOLING: Flash-Free Molding: Part Two

Parting-line maintenance, mold spotting, and machine conditions can all contribute to flash.

Read More