Tooling

Fakuma Show News: Hot Runners & Tooling

Hot-runner nozzles, manifolds, and controls, as well as other mold components and a new tooling concept made their debut in Friedrichshafen.

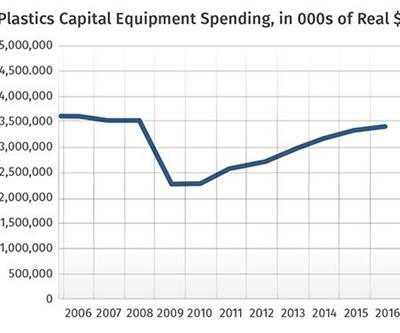

Read MoreProcessors’ Equipment Investment Plans Remain Strong in 2016

Gardner鈥檚 exclusive research forecasts total spending on primary processing and auxiliary equipment at its highest level since 2008.

Read MoreTOOLING: Designing Molds for Easy Cleaning & Maintenance in the Press

Pay attention to water leaks and rust, proper grease selection, vent buildup, and checks for wear.

Read MorePriamus Joins Stable of Hot-Runner Suppliers

Three hot-runner makers and a controls supplier come under the same umbrella.

Read More3D Printing’s Growing Presence Seen at Fakuma Show

Additive manufacturing appeared in tooling inserts, robot grippers, and molded parts.

Read MoreTOOLING: Designing Molds for Easy Maintenance in the Press, Part 1

Attention to design of cooling, ejection, and slides can save downtime and maintenance headaches.

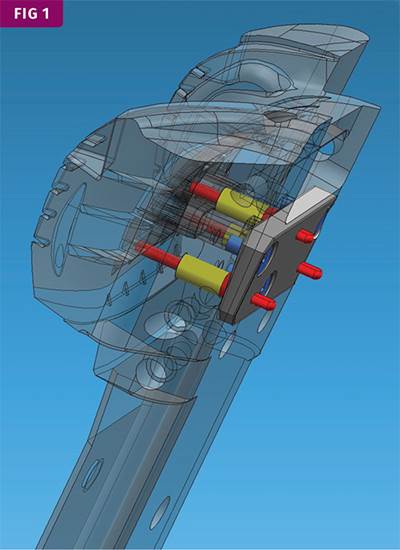

Read MoreTOOLING: Dealing with Lifters--Part 2

This installment delves into more detail on some variables of design and fitting/timing of the lifters, which can cause issues or failures during molding.

Read MoreServo Valve-Gate Helps Auto Parts Weigh Less & Look Great

More uniform and lower pressure makes a thinner, better part.

Read MoreShiny New Hot-Runner Plant Is High Tech Showplace

HRSflow employs automation, sophisticated software tools in its first North American production plant.

Read More