Tooling

R&D Agreement Seeks to Advance Additive Manufacturing in Tooling

AddUp and Oak Ridge National Laboratory announced a $2.7 million cooperative R&D deal to advance laser powder bed fusion (LPBF) technology in toolmaking, including for conformal cooling.

Read MoreSave Time, Money: Use a Mold-Design Checklist

Here are 15 examples of common molding issues that occur during an initial mold trial. Many of them could be avoided or corrected with a proactive checklist.

Read MoreHRSFlow and RJG Pair Technologies for Advanced Process Control

By pairing HRS Flow’s servo-driven FLEXflow hot runner with RJG’s sensors and eDART controller, the collaborators say they’re able to sequence mold filling based on what’s actually happening in the tool vs. time or screw position.

Read MoreNew Molding & Moldmaking Event in Mexico Finds Success in Launch

The inaugural Meximold drew nearly 4000 attendees to Querétaro from all segments of the injection molding and moldmaking supply chain, with dates set for 2020 as more than 90% of exhibitors renewed their participation.

WatchiD Additives Names PCS Company the Exclusive U.S. Distributor of Rust Removal System

Effective immediately, PCS is the exclusive distributor to injection molders and moldmakers in the U.S. for iD Additives’ iD Eco-Pro 360 rust removal systems.

Read MoreHot Runners: Controller Adds Industry 4.0 Functionality, Set-Up Assistant

The latest iteration of Meusburger’s profiTEMP+ hot runner controller supports EUROMAP 82.2 for data exchange between injection molding machines and hot runner controllers.

Read MoreHot Runners: Nozzles, Valve Gate Unit & Control Announcements

Meusburger’s PSG brand expanded the smartFILL nozzle series; provided pneumatic and hydraulic operating units for valve gate nozzles and combined the VCON controller with the profiTEMP+ in one cabinet.

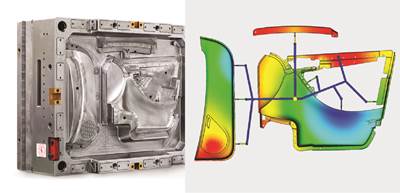

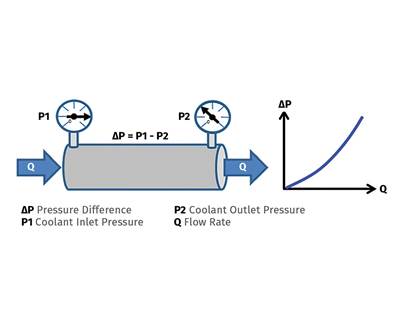

Read MoreIs Your TCU Up to the Job? Mold Simulation Can Give the Answer

For realistic results, molding and cooling simulation must reflect the capabilities of the actual TCU to be used. Here’s how simulation can help determine whether your TCU is up to the job.

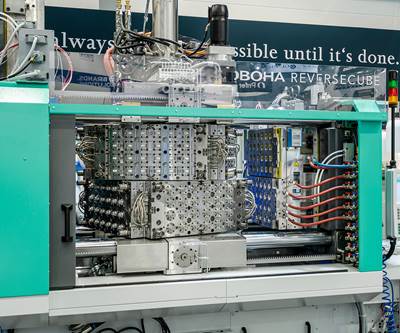

Read MoreTooling: ‘Reverse Cube’ Puts New Spin On Two-Component Molding

For two-component molding, splitting the cube mold into halves that rotate in opposite directions provides thermal isolation and long cooling times for both materials.

Read More