HRSFlow and RJG Pair Technologies for Advanced Process Control

By pairing HRS Flow’s servo-driven FLEXflow hot runner with RJG’s sensors and eDART controller, the collaborators say they’re able to sequence mold filling based on what’s actually happening in the tool vs. time or screw position.

HRSFlow and RJG revealed the fruits of a new collaborative effort to control the sequencing of servo-driven valve gates on the basis of what’s happening inside the mold cavity, improving process consistency and part quality while opening up new design dimensions and allowing the use of smaller tonnage machines.

The addition of sensors detecting temperature, pressure and deflection, allow the family mold to run parts of widely disparate dimensions.

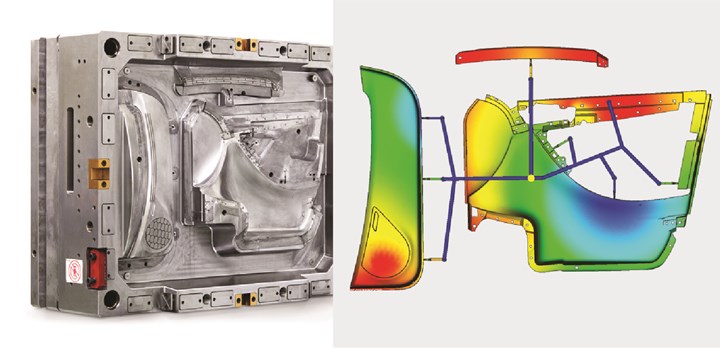

In December at HRSFlow’s North American headquarters in Byron, Center, Mich., the companies showcased the technology on a family mold featuring three different components with different weights, wall thicknesses and surface areas. The mold, which includes a door panel (560 cm3; 2.3-mm wall), map pocket (338 cm3; 2.4-mm wall), and a bracket (58 cm3; 3.0-mm wall), was run by the company at K 2019, showing the potential its FLEXflow hot runner system holds for family molds of parts with disparate dimensions.

The difference this time was the addition of five pressure sensors, six mold deflection sensors, and five temperature sensors spread throughout the tool. These sensors fed information to an RJG eDART module, which in turn, controlled the FLEXflow system, independently manipulating the mold’s eight gates for what Robert Harvey, HRSFlow’s North American sales director calls independent cavity control.

Normally, all cavities would see the same pressure, dictated by the injection piston, so that in a family mold a smaller cavity might be subjected to more pressure than it needs, increasing the risk for flash or molded-in stress that could result in warp. With this setup, Harvey says each cavity effectively gets its own pack-and-hold profile, making the process completely independent of the machine.

“Sequencing based on mold-based events rather than time or screw position, allows a process to be responsive to actual conditions in real time,” Harvey explains. Other benefits include the ability to minimize risk with a new tool launch, owing to the ability to simulate FLEXflow before cutting steel, as well as enabling robust process development that can create a larger process window and more consistent quality. The ability to consolidate parts into a single tool can reduce a project’s total tooling cost, and by knowing exactly how much clamp force is required to fill the cavities without flashing the tool, the possibility to use less force, and a smaller machine, opens up.

Harvey says beyond automotive, his company sees potential application of the technology in the appliance, transportation, environmental, furniture, and lawn and garden markets, among others.

By pairing HRS Flow’s Flexflow with RJG’s eDART, a molder can control the hot runner system based on conditions within the tool.

Related Content

-

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

-

Pressure Tester Checks Molds for Water Leaks

Globeius is offering the Mouldpro pressure tester for detecting water leaks within an injection mold’s cooling circuit.

-

MPM’s Second Act: Keeping Injection Molding, Moldmaking in the Midwest

Larry Austin’s 35 years at a highly successful injection molding company inform much of what he does and doesn’t want in his second act in plastics owning an injection molding company.