processing tips

Follow These Tips to Power Up Your Purging Process

A properly executed purging process can save processors thousands a year in lost production while helping them increase output and avoid scrap. Here’s how to optimize your results.

Read MoreTooling: Tunnel Gates for Processors, Part 2

What you need to know to overcome problems out on the production floor.

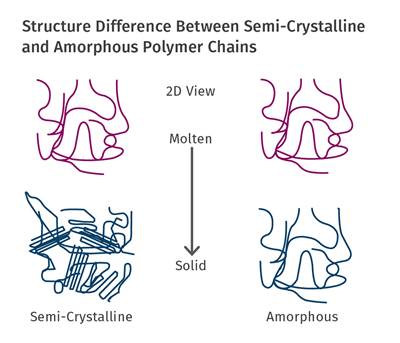

Read MoreInjection Molding: Melting Amorphous vs. Semi-Crystalline Plastics

Understanding the differences in how each melts is crucial to obtaining melt uniformity.

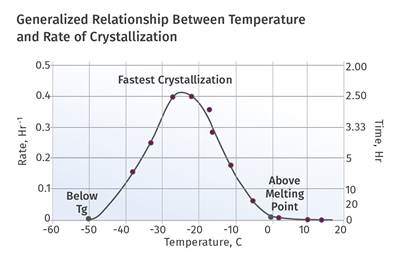

Read MoreA Processor’s Most Important Job, Part 2: Crystallinity

Process conditions help determine the difference between the maximum degree of crystallinity that can be achieved in a polymer and the degree that is present in a molded part.

Read MoreAir-Ring Upgrade Pumps Up the Output

Film processor Dallas Plastics boosts throughput by as much as 40% by retrofitting a new air ring—without the need for IBC.

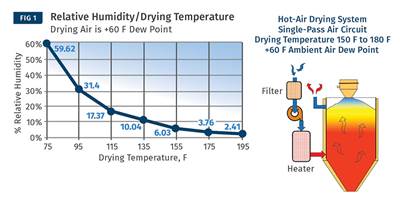

Read MoreWhy Drying Polyolefins Might Be Right for Your Process

From a technical standpoint, drying non-hygroscopic materials such as polyethylene and polypropylene may not be necessary. However, doing so may be advantageous to your process. Here are details.

Read MoreDetermining Vent Depths in Injection Molding

Experiments reveal the relationship between vent depths and part thickness, allowing molders and moldmakers to more precisely determine vent dimensions.

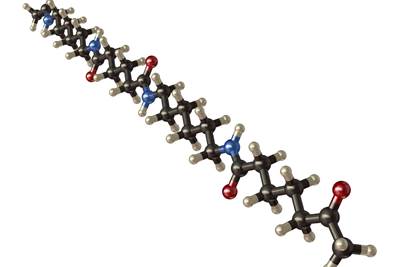

Read MoreA Processor’s Most Important Job, Part 1: Molecular Weight

Many processors don’t realize that preserving material characteristics is crucial to product success and failure. The focus here is on molecular weight.

Read MoreWhat You Can Learn From Pharma Compounders

Twin-screw extrusion has been a standard in plastics compounding for decades but has only recently been embraced by the pharmaceutical industry. Here’s what plastics compounders might learn from the ‘newbies’ to help make a better, more consistent product.

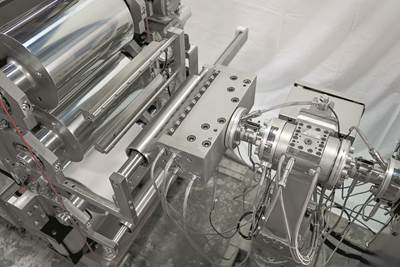

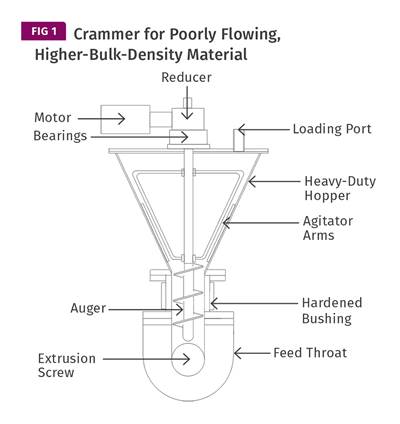

Read MoreExtrusion: How Hopper Crammers Can Help Feeding

A crammer can assist the flow of certain polymers into the extruder. But the design is not universal and very material dependent. Here’s what you need to know.

Read More