processing tips

When to 'Adapt,' When to Retool?

That is the question pipe and tubing processors typically confront when they specify a line for one product, only to have to add to the product mix when ´óĎó´«Ă˝ conditions change. Here are some tips to guide you to the right answer.

Read MoreThe 'Butterfly Effect' in Injection Molding—A Connected Process

In injection molding, a seemingly minor change in a setpoint can have a significant impact on part quality and process robustness and repeatability. That’s why Scientific Molding focuses on process outputs, not setpoints.

Read MoreSolving the Bane of Stretch-Blow Molding: Off-Center Gates

There are many reasons why off-center gates happen, and processors should be aware of all of them to quickly find the ones causing the problem.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

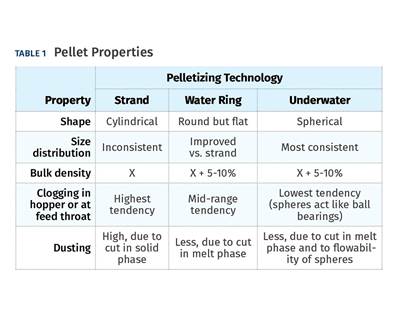

Read MoreFollow These Guidelines to Select the Right Pelletizing System

Which pelletizing system is right for your application? Is the one you’re using today necessarily the right choice for tomorrow? Here’s is an analysis that can help you decide among the three major options.

Read MoreProcess Capability and the ‘Hesitation Effect’

Understanding the concepts of pack and hold and applying them during process development is critical for molders to achieve consistent part quality.

Read MorePART 2: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. In part one we covered the why. Here’s the how.

Read MorePart 1: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. Here’s why.

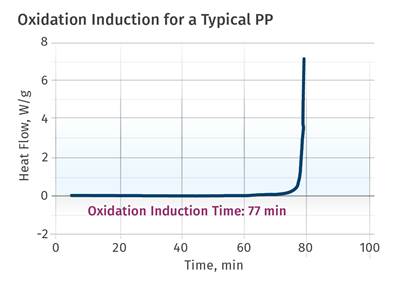

Read MorePart 11: A Processor's Most Important Job

It’s the processors job to ensure molded parts contain enough stabilizer to perform to the expectations of the end use.

Read MoreA Gel By Any Other Name...

Gels…unmelt…contaminants…inclusions…whatever you call them, you want to avoid them. Proper maintenance and good housekeeping—lids on boxes, closed hopper doors, core-free reclaim systems—go a long way towards defect-free product.

Read More