processing tips

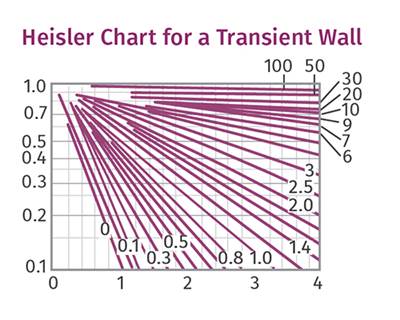

EXTRUSION: Cooling: The Critical Function in Extrusion

Figuring out how much cooling your process needs is complicated. But there are ways to approximate.

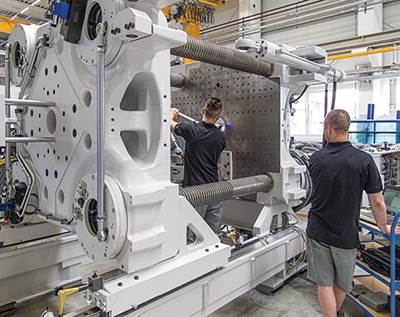

Read MoreINJECTION MOLDING: How to Specify an Injection Molding Machine

With the market percolating, more molders are looking at new presses. This series will discuss what you should consider before writing a check, beginning with the clamping unit.

Read MoreMolder Cuts Post-Purge Costs and Downtime in Half

By switching to a new purging compound, IMCO now can complete a changeover in 10 min.

Read MoreShredding Thin Film: How to Do It Right

While many processors recoil at this task, a little know-how in shredding equipment, processing, and maintenance should add the necessary confidence.

Read MoreKnow Your Options for Foaming Sheet

Tandem extrusion of PS is still the standard technology, but new materials options and equipment technology are emerging.

Read MoreTen Tips to Slash Cycles in PET Preform Molding

Here are some tricks of the trade to make your preform processing more productive, even if you don’t have the latest souped-up press.

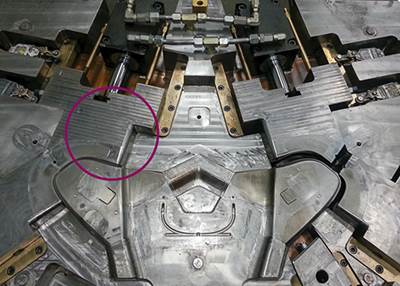

Read MoreTOOLING: Venting: A View From the Trenches

Venting is a prime culprit for molding problems, partly because toolmakers and process techs have different ideas of what’s needed.

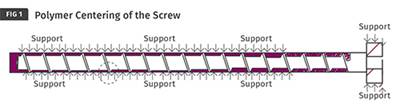

Read MoreEXTRUSION: Here’s Why You Shouldn’t Run Your Extruders Dry

At least not for longer than a few minutes. The thin film that’s captured between the screw flights and barrel wall supports the screw and acts as a lubricant. Without it, galling can occur.

Read MoreINJECTION MOLDING: Scientific Molding Gone Wrong

Sometimes molders get trained in Scientific Molding only to revert to their old way of doing things as soon problems pop up.

Read MoreMATERIALS: The Trouble with Data Sheets

Data sheets are routinely relied upon, yet the data they provide is limited in scope and can lead to incorrect conclusions.

Read More