Postprocessing

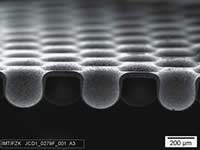

Micro-Thermoforming Makes Its Debut

Manufacturers of micro-size components that until now relied exclusively on injection molding may have another option to consider.

Read MoreSolve Ultrasonic Horn Problems With Finite-Element Analysis

Computer modeling with 3D finite-element analysis (FEA) is used in the plastics industry because it can identify stresses, predict performance, and analyze part failures that can often be missed by traditional 2D modeling methods.

Read MoreNPE 2006 News Wrap-Up: New Materials and Equipment for Decorating In and Out of the Mold

Among the latest developments in decorating and printing at the NPE show in Chicago were digital printers, flexographic printers for bags, and scratch-resistant heat-transfer foils for hot stamping and in-mold decoration (IMD). Also featured was new equipment for laser marking and engraving and an electrostatic charger for in-mold labeling (IML). News in stamping foilsSolidBrush metallic finishes are the latest heat-transfer foils from Kurz Transfer Products.

Read MoreLearning to Master In-Mold Labeling

As in-mold labeling, or IML, attracts a growing following among U.S. molders, some are finding that mastering a complex new technology is no small task.

Read MoreNew Web Source of Parts for Ultrasonic Welders

A new online “Web store” for ordering parts for ultrasonic welders is www.tributek.biz, located in Elburn, Ill.

Read MoreNPE 2006 News Wrap-Up: Thermoforming

Several new processing technologies unveiled at NPE point to thermoforming’s growing capability to produce in-mold labeled and decorated plastic parts.

Read MoreHerrmann Ultrasonics Moving to New HQ

Herrmann Ultrasonics, Inc., maker of welding and bonding equipment, plans to move next month from Schaumburg, Ill., to new headquarters in Bartlett, Ill.

Read MoreWhat to See at NPE 2006: Decorating, Printing and Finishing

While there is plenty of news at NPE this year in pad, screen, dry-offset, flexo, and inkjet printing, as well as laser marking, hot stamping, heat-transfer decorating, and some less familiar technologies—the real star of the show is summed up in two words: “in-mold.” Responding to excitement in automotive, appliance, and electronics industries, at least 19 companies are showing materials or equipment for in-mold film-insert decorating or labeling (IMD, IML) for injection molding and thermoforming.

Read MoreWhat to See at NPE 2006: Welding, Bonding and Assembly

Systems integration and compact size will be central themes of welding exhibits at NPE, where a wide range of new products will be displayed.

Read MoreImproved Machines and Molds Highlight Fall Rotomolding Show

Worldwide commercial availability of “ovenless” rotomolding machinery, new cast-aluminum molds that provide faster cycles, improved material pulverizing systems, and new graphic transfer systems for engineering materials such as nylon were unveiled at the 30th Annual Fall Meeting of the Association of Rotational Molders (ARM), held in Chicago last fall.

Read More