Postprocessing

Advances in Materials, IML and Tooling Highlight Rotomolders' Meeting

Several new resins and additives that raise part performance and improve processability were launched at the recent 32nd Annual Fall Meeting of the Association of Rotational Molders (ARM) in Detroit.

Read MoreThe Future of Vinyl Siding Fighting Back with Foam, Fiber Composites, and Even Paint!

Under attack from fiber cement, PVC siding makers are exploring different technologies to shore up their future.

Read MoreAuto Glazing: Film, Coinjection & Coating Technologies Advance

Hard-surfacing options for molded plastic glazing now include plasma instead of wet coatings–and replacing coatings altogether with in-mold film lamination or multi-layer coinjection.

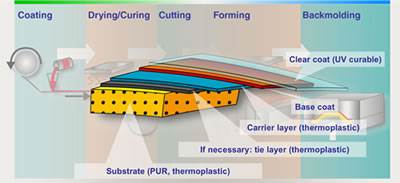

Read MoreDual-Cure PUR Coatings Boost Performance Of In-Mold Decorating Films

A new version of in-mold decorating technology, developed initially for exterior auto body components, uses dual-cure coating technology to provide a paint film that is both stretchable for good thermoformability and also provides the high gloss and durability of conventional paints.

Read MoreHexion to Buy Huntsman Corp.

Huntsman Corp., Salt Lake City, has agreed to a defi nitive merger agreement with Hexion Specialty Chemicals, Inc., Columbus, Ohio, an Apollo Management, L.P. portfolio company and a global leader in thermoset resins, including vinyl esters, unsaturated polyesters, and epoxies.

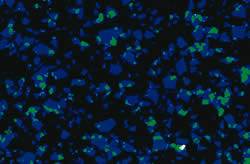

Read MoreNanocomposites: Less Hype, More Hard Work On Commercial Viability

Nano-fillers for enhancing thermoplastics and thermosets continue to make headway in commercial applications, although at a slower pace than had been anticipated.

Read MoreThermoforming: Ready for In-Mold Labeling?

After several fits and starts over the last decade, thermoforming IML appears ready for prime time, thanks to improvements in output and labeling technology. For now, the action is mostly in European packaging.

Read MoreRigid Packaging Goes Lighter, Thinner With Microcellular Foam

Molding higher volumes of a rigid thin-wall part typically means going to a larger press for increased injection and clamping capacity.

Read MoreAdhesion Promotion: Now Plasma-Treat the Resin, Not the Molded Part

A new approach to plasma treating applies the treatment to resin pellets or powder in order to achieve enhanced adhesion of paints, glues, or foamed-in-place urethanes to the molded part.

Read More