Pipe, Profile & Tubing Extrusion

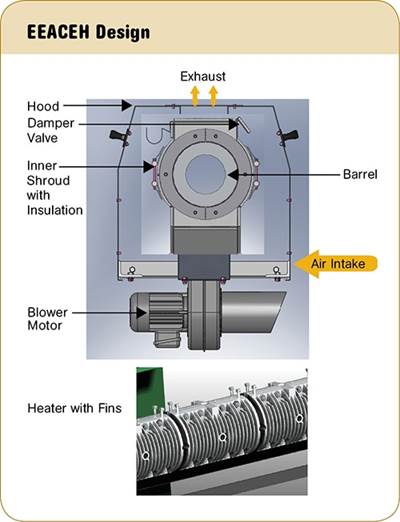

New Barrel Heater/Cooler Saves ‘Juice' to Run an Extruder

New, patent-pending design is said to reduce both radiant and convection heat losses.

Read MoreDead Screw Talking

There's a lot you can learn by conducting a post-mortum examination of your screw.

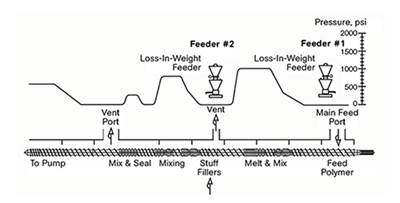

Read MoreLook Before You Leap: When Direct Extrusion Makes Sense

The process offers great opportunities to extrude a better product at less cost, but it’s not for everyone. The formulation, product mix, and anticipated volumes must be carefully assessed to determine whether DE is the preferred manufacturing methodology.

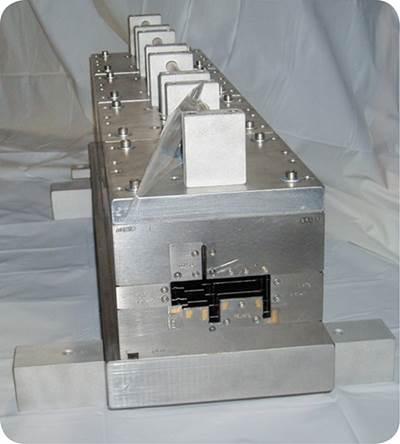

Read MoreHow To Size & Calibrate Profile Parts

Doing it right is critical to maintaining profile dimensions.

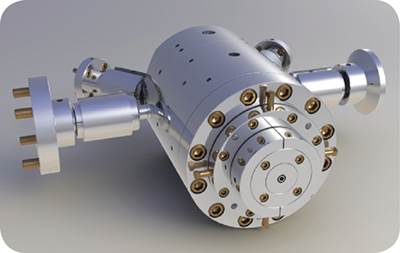

Read MoreKnow the Three F’s Of Profile Tooling Design

Designing an extrusion profile and ultimately the die design and sizing equipment cannot be executed successfully without a full understanding of the customer鈥檚 quality expectations or specifications.

Read MoreNanolayers Come to Tubing

Nanolayer technology, an active area of development in films, is also making its way to tubing extrusion.

Read MoreFour Keys to Consistent Tubing

Because of their use in critical applications, processors of medical tubing have little or no room for error.

Read MoreOn Site: Growth Through Innovation in Medical Tubing

By focusing on high-tech, quick-turnaround, turnkey solutions, Putnam Plastics has grown into a leader in the field of medical extrusion.

Read MoreTips and Techniques: How to Mold & Extrude Using Chemical Foaming Agents

Here are some tips and techniques for extruders and injection molders to refer to when using CFAs.

Read More