Materials Know How

Dimensional Stability After Molding: Part 1

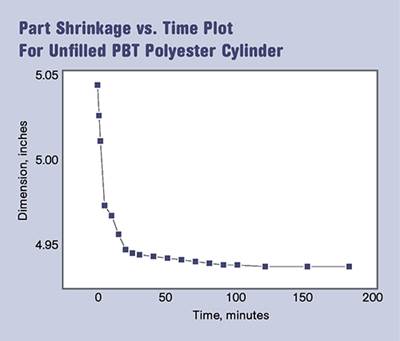

The degree to which molded parts shrink as they cool is largely dependent upon the composition of the material being processed.

Read MorePBT & PET Polyester: Part 2 The Performance Factor

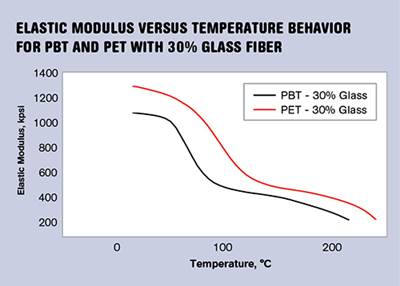

All things being equal, PET will outperform PBT mechanically and thermally. But the processor must dry the material properly and must understand the importance of mold temperature in achieving a degree of crystallinity that allows the natural advantages of the polymer to be realized.

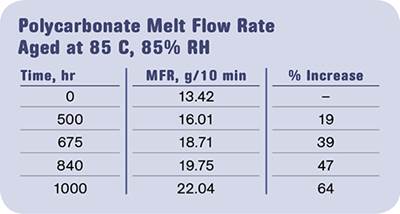

Read MoreUse MFR Cautiously with Filled Materials

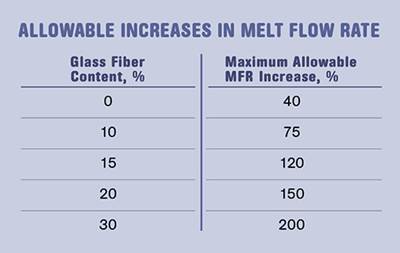

If melt flow rate tests are used to evaluate the effect of processing on the average molecular weight of the polymer, the applicable rules must consider the contribution of the filler to the test result.

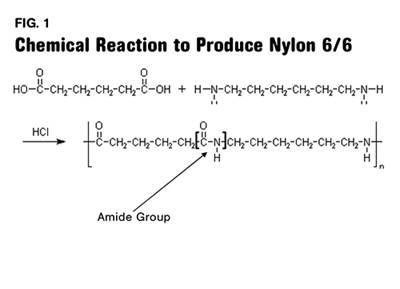

Read MoreWhen It Comes to Nylon, Don’t Do the Math

Chemistry is seldom as simple as it looks. Polymer chemistry takes the complexity up a notch. Nylon chemistry is about much more than doing the math.

Read MoreBiopolymers: Time to Take A Deep Breath

Are we looking at all of the implications associated with developing this new 'crop' of polymers?

Read MoreWorking with Color Concentrates

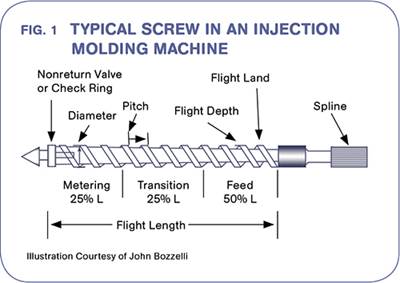

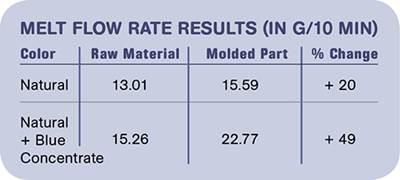

Industry needs more development of enhanced-mixing screws.

Read MoreWorking with Color Concentrates

Perhaps the greatest difficulty involving the use of color concentrates is specifying them appropriately for the material to which they are being added.

Read MoreWorking with Color Concentrates

Because the consumer sees so many colored plastic articles, it is natural to assume that the process of achieving molded-in color is a simple one. Those of us in the industry know differently.

Read More