Materials Know How

MATERIALS: Analysis Gone Wrong

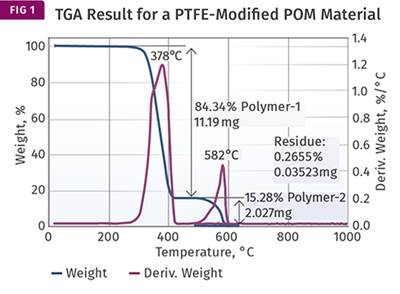

A lot of resources are devoted each year to trying to figure out why products fail. Sometimes it’s because no one involved in a project realizes the data provided was wrong.

Read MoreThe Mystery Of Physical Aging, Part 3: Accelerated Aging Tests

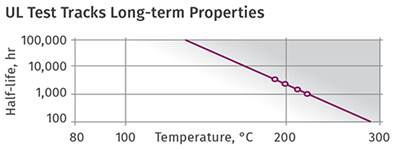

Accelerated aging tests relied on by industries such as medical take into account only chemical aging—oxidation—and ignore physical aging.

Read MoreThe Mystery of Physical Aging, Part 2: Slow Down Aging

Dimensional and property changes depend on the size of the part, molecular weight of the resin, and processing conditions.

Read MoreThe Mystery of Physical Aging, Part 1: Knowing the Difference

In polymers, aging is commonly considered essentially synonymous with oxidation. But there are important differences between this type of chemical aging and less commonly recognized physical aging. Let’s unlock the mystery.

Read MoreMATERIALS: Don’t Guess Your Way through Root Cause Analysis: Part 2

The huge chasm between the laboratory and manufacturing discipline usually does not lend itself to problem-solving. It can be improved with clear communication between the analysis laboratory and the people bringing the problem to the lab.

Read MoreMATERIALS: Don’t Guess Your Way Through Root Cause Analysis

More than 50 different polymer test techniques can be used to find root causes of problems. Of these, five or six are fairly common. Use them to take the guesswork out of why a product failed.

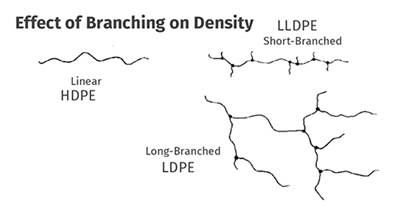

Read MoreMATERIALS: Performance in Polyethylene: Density Matters: Part II

Remembering the case of the failed gas tanks.

Read MoreMATERIALS: Performance in Polyethylene: Density Matters

In polyethylene, density provides another mechanism to control properties. But it must be specified properly.

Read MoreMATERIALS: Melt Flow Rate Testing—Part 10

Two areas where the melt flow rate test it is not useful are related to processing.

Read More