Materials Know How

Melt Flow Rate Testing—Part 6

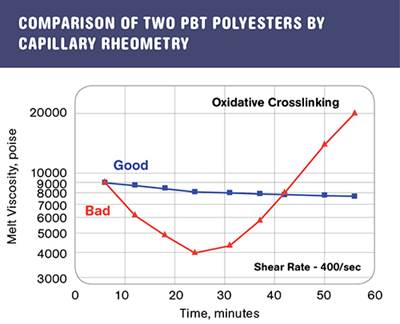

Once degradation has been established, the discussion inevitably turns to how it happened. It might be expected that the answer to this question is widely known. Not so. The good news is that the influences that cause polymer degradation during processing are few.

Read MoreMelt Flow Rate Testing—Part 5

There are two points in the manufacturing supply chain where a determination of average molecular weight (MW) is important. The first is when the material is first received by the molder. The second is after molding.

Read MoreMelt Flow Rate Testing—Part 4

Few molders perform the test in-house. Of those that do, most don't understand why they are doing it or what they are measuring.

Read MoreMelt Flow Rate Testing—Part 3

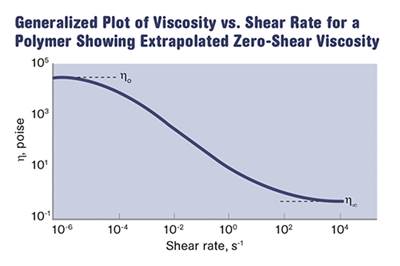

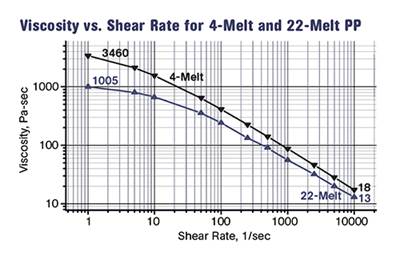

There is a well-established relationship between something called the weight-average molecular weight of a polymer and a parameter known as the zero-shear viscosity.

Read MoreMelt Flow Rate Testing – Part 2

To fully appreciate the strengths and weaknesses of the melt-flow-rate (MFR) test it is important to know something about the way the test is performed.

Read MoreDimensional Stability after Molding—Part 5

All materials possess a property called the coefficient of thermal expansion (CTE). The vast majority of materials increase in size as their temperature increases and decrease in size as their temperature declines.

Read MoreDimensional Stability After Molding: Part 4

In the first three parts of this series we focused on those influences that cause molded parts to get smaller. But there are environmental factors that also cause parts to increase in size over time.

Read MoreDimensional Stability after Molding—Part 3

Any process that involves melting and re-solidifying a polymer involves a compromise between achieving the perfect structure and producing a part that can be sold at a price that the market is willing to pay.

Read MoreDimensional Stability After Molding—Part 2

After molding, acetal parts can continue to shrink at room temperature and even in the cold.

Read More