Know-How

How To Identify Resin Degradation in Single-Screw Extruders

Degradation can occur in many single-screw extrusion operations, and typically occurs due to minor design flaws in the screw. Here is how to track it down.

Read MoreBulk, Solid and Melt Density: How to Calculate These Values and Why They Matter — Part 2 of 2

Understanding and calculating solid density and melt density will help molders with everything from material and machine selection to determining piece part costs.

Read MoreOptimizing Melt-Fed Single-Screw Extruders on Compounding Lines

The main problem with melt-fed extruders that are starve-fed is setting the depth of the metering channel. In this scenario, we describe how this problem was solved.

Read MorePolymer Showdown — PC/ABS vs. PC/PBT — May the Best Material Win

First in a series, experts from plastics engineering consultancy The Madison Group will pit leading thermoplastics against each other to see how they differ in processing characteristics, chemical resistance, thermal and mechanical performance, and more.

Read MorePolymer Science for Those Who Work With Plastics: Molecular Weight — What It Is and Why It Matters

Molecular weight might seem like an abstract concept, but it plays a crucial role in determining the behavior of plastics during processing and in their final applications.

Read MoreWhat You Need to Know About Roll-Cooling Design

Cooling rolls might not look like high-tech machines, but the fact is there is a surprising amount of technology involved in their design, manufacture and use. Here’s what you need to know.

Read MoreTo Cushion or Not To Cushion: That Is the Question

Whether or not your process setup includes adding cushion depends on multiple factors, including the part being molded. Learn when and how to effectively apply cushion in your process.

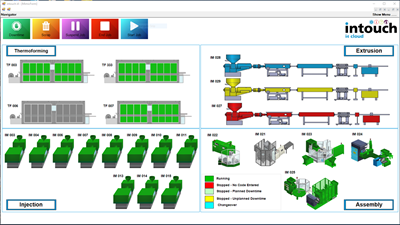

Read MoreProcess Monitoring or Production Monitoring — Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

Read MoreBest Practices for Engraving Cores and Cavities

Consider depth, font style, artwork size, polarity and location when engraving.

Read MoreWhat You Need to Know About Melt-Temperature Measurement in Single-Screw Extruders

Measuring the discharge temperature is not so simple, especially when using thermocouples positioned in the transfer line just upstream of the die.

Read More