Injection Molding

Why Long-Glass Molders Are Compounding In-Line

Compounding raw fiberglass directly into thermoplastic molded parts is growing rapidly in Europe, and now it鈥檚 coming here. D-LFT, as it鈥檚 called, promises to make large parts cheaper and stronger鈥攂ut with new technological risks and higher up-front investment costs.

Read MoreElectric Machines and New Processes Catch Fire

The October show in Dusseldorf saw an onslaught of new all-electric and hybrid-electric presses, with modular designs, new clamping styles, and new sizes available from an ever-growing range of suppliers.

Read MoreMetallocene VLDPE Is a Tough New Contender for Flexible Packaging

A new metallocene catalyzed, very-low-density polyethlyene (mVLDPE) from ExxonMobil Chemical Co., Houston, reportedly offers the excellent toughness associated with mLLDPE plus lower heat-seal temperatures and other advantages over conventional Ziegler-Natta VLDPEs or ULDPEs for flexible packaging.

Read MoreCoinjection's New Look: Two Screws, One Barrel By Mikell Knights

Coinjection molding has always been viewed as a cost-saving technique that can put a lower cost material such as off-spec, recycled, unpigmented, or foamed resin into the core of a two-material sandwich. Coinjection also aids a molder looking to make value-added products such as soft-touch parts or ones with a cosmetic surface over a glass-reinforced core.

Read MoreFuel Cells Jolt Plastics Innovation

Optimists view fuel-cell vehicles and power appliances as a coming bonanza for plastics processors. They see potential demand for billions of pounds of thermosets and engineering thermoplastics in plates, membranes, manifolds, pumps, plumbing, and more. But molding challenges and cost hurdles mean success won’t come easily.

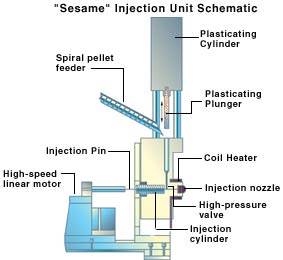

Read MoreMold Micro Parts Just One Pellet at a Time

Here is a closer look at the unusual micro-injection molding press that was reported briefly in our October issue.

Read MoreExternal Gas Molding Squeezes Out Sinks

External gas injection is finally getting molders’ attention as a means to improve part surface quality. Two different approaches are available for licensing. Here’s a look at the processes, the potential benefits, and the commercial players.

Read MoreNanocomposites Broaden Roles in Automotive, Barrier Packaging

Nanocomposites are gradually gaining acceptance in the mainstream of global plastics processing. These polymer compounds, containing relatively low loadings (under 6% by weight) of nanometer-sized mineral particles, are beginning to show up in polypropylene and TPO-based automotive exterior claddings, barrier beer bottles, nylon packaging films, polyethylene pipe and wire/cable coatings, and more.

Read MoreAC Variable-Speed Drives Raise Molding Productivity

A more economical approach than either all-electric servo drives or special hydraulic pump packages is offered by Magnum LLC, Garden Grove, Calif. It is one of several firms that retrofit AC induction pump motors with variable-speed drive systems in place of the usual fixed-speed pump motor.

Read MoreThe Right Way & The Wrong Way To Add Materials Conveying Capacity

Whether you're expanding your current plant or consolidating operations and moving equipment from one location to another, you will need to make sure that your material-handling system delivers the productivity you expect.

Read More