Injection Molding

3D Systems Launches Rapid Parts Service

3D Systems Corp., Rock Hill, S.C., a supplier of 3D printing, rapid prototyping, and rapid manufacturing equipment and materials, has acquired Acu-Cast Technologies, Lawrenceburg, Tenn., a provider of prototyping services.

Read MoreNew Concept for Multi-Shot Molds

Production of multi-color or multi-material articles on a conventional injection press without additional equipment is enabled by new tooling technology from German moldmaker Zahoransky Formenbau GmbH.

Read MoreNew Desktop 3D Printer Comes to U.S.

WEB EXCLUSIVE: Solido of Israel recently launched a new desktop 3D printer and announced two U.S. distributors.

Read MoreNew Alliance in PET Preform Molds

ABBA Systems Ltd., Brantford, Ont., and Mold-Masters Ltd., Georgetown, Ont., are teaming up to supply complete PET preform injection molds under the name iPET Systems.

Read MoreServo Robots Show More Speed, Muscle & Brains

The recent NPE 2009 show in Chicago saw the debut of dozens of new and enhanced robots for injection molding. The vast majority of the new models were all-servo types, though some economized by mixing servo and pneumatic axes. These new robots emphasized higher speeds, heavier payload capacity, longer reach, and more intelligent controllers that make programming and troubleshooting easier than ever. Telescoping arms and dual arms were very common among the new entries, as well.

Read MoreNPE 2009 Wrap-Up: New Machinery for Injection Molding

New injection machinery at the show ranged from all-electric units for high-speed packaging or bioplastic processing to hybrid presses ready for the cleanroom. Other units highlighted multi-component molding with LSR and thermoplastics or super-compact presses for small parts. Several new machines targeted specific applications such as caps and closures, PET preforms, LSR, or integrated long-glass compounding.

Read MoreCooling in Tough Times: How to Save Energy and Maintenance

In today’s down market, plastics processors are discovering a whole new set of problems related to operating at reduced capacity.

Read MoreHow to Clean Screws Nondestructively

Maintenance departments often clean screws wrongly, causing serious and expensive damage.

Read MoreAluminum Tooling Proves Its Mettle

Can aluminum tooling enter the race for high-volume automotive injection molding?

Read MoreExternal Benchmarking of Injection Molding Energy Efficiency

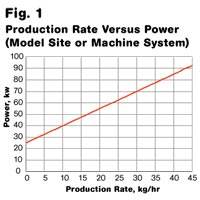

In April, we discussed the use of the slope of the curve of process energy consumption versus production volume for internal benchmarking of energy efficiency.

Read More