Injection Molding

Know Your Plant’s ‘Energy Fingerprint’

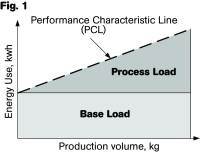

It is commonly thought that energy use in plastics processing is fixed and uncontrollable.

Read MoreWhy Not Just Let ’r Leak?

Here’s how a typical West Coast molding facility with 20 injection presses investigated the downtime impact of water leaks in the plant.

Read MoreIntroduction to Energy Management For Plastics Processors

Energy efficiency is one of the “hot” topics of the 21st century and plastics processors around the world are trying to come to terms with it.

Read MoreModular ‘Adaptable Automation’ Makes IML More Economical

Five years ago, in-mold labeling was just gaining traction among North American injection molders as a one-step approach to decorating without secondary operations.

Read MoreYour Business Outlook - January 2009

Domestic output of injection molded packaging decreased by 6% in 2008, and the decline accelerated as the year ended.

Read MoreGet a Grip on Screw Slippage

Screw slippage occurs when the screw in the barrel of the injection machine has difficulty picking up material from the feed throat or is unable to develop enough tack to convey the material down the length of the barrel.

Read MoreInjection Molding: Taiwan Machine Builders Focus on All-Electrics, Hybrids and IML

There was a brand-new emphasis at this year’s Taipei Plas, the premier plastics exhibition for Taiwanese injection machine builders.

Read MoreUnbalanced? No Shortage of Ways to Fix Uneven Filling of Multi-Cavity Molds

The accepted ground rule for balancing melt flow in multi-cavity injection molds is to achieve equal flow distance from the injection point to each cavity.

Read MoreNovel Ejector System Eliminates Plates and Pins

Injection mold cost savings, greater molding productivity, and better part quality are promised for a new ejection system that does away with conventional ejector plates, housings, pins, and risers. This approach is said to reduce mold height, shorten mold-open times by at least 10%, enable better optimization of mold cooling鈥攏ot to mention eliminating ejector marks on parts.

Read MoreHow IML ‘Cuts the Mustard’ in Germany

The lightweighting advantages of in-mold labeling in times of soaring resin costs are highlighted by the experience of Germany’s largest mustard maker.

Read More