industry 4.0

Automation: Six-Axis Robot Fits In Your Hand

Mecademic’s new baby handles up to 1.1 lb with very high accuracy.

Read MoreFour New Developments in Plastics Drying

These four short videos provide a snapshot of what’s going on in plastics resin drying technology. Yes, there’s Industry 4.0, but also lots more to bring higher quality and efficiency to your injection molding and extrusion processes.

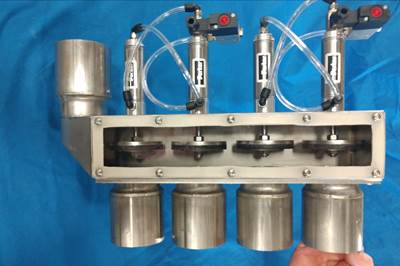

Read MoreMaterial Handling: Versatile Diverter Valve Meets Industry 4.0 Objectives

Standard sizes are 1.5-4 in.; the unit can be easily mounted horizontally or vertically.

Read MoreIndustry 4.0 Gives DMT a Sharper Edge

Leading maker of blade sharpeners boosts productivity in captive molding with cutting-edge connectivity.

Read MoreBringing Industry 4.0 to Plastics Auxiliary Equipment

With all this talk about Industry 4.0, getting your whole plastics processing plant “connected” can still seem a little daunting. New equipment monitoring systems make it less so by making it easier to bring all of your auxiliary equipment together into a single platform. (Sponsored Content)

Read MoreAugmented Reality on the Shop Floor: Reimagining the Instruction Manual

If augmented reality technology providers have their way, equipment manuals and instructional videos could be headed to obsolescence.

Read MoreMore Automation = More Capable Robots

More complex automation tasks require use of six-axis robots, often in combination with linear robots, as well as use of machine vision, SCARA robots, and collaborative types.

Read MoreThermal Care Brings Industry 4.0 to Process Cooling

Improved PLC control capabilities and the introduction of a new Industry 4.0 inspired software platform are among the highlights of Thermal Care’s NPE2018 booth (W3163).

Read MoreRobots Play a Role in Industry 4.0

Robots are gaining the ability to monitor their internal systems for remote troubleshooting and predictive maintenance. They also are reporting production data.

Read More