Film Extrusion

10-Layer, 10-Extruder Nano Blown Film: A Russian First

Films produced on this line are next-generation nanocomposite barrier films for food packaging.

Read MoreLooking into Photovoltaic Film? Here Are Material & Die-Design Insights

The market for high-tech film or sheet used in solar modules represents a considerable opportunity for specialty extrusion processors looking to expand into high-end industries and capitalize on the global shift toward alternative energy.

Read MoreCut Material Waste With Accurate Gauge Measurement

Gauge control done right can save you big money on materials and improve quality to boot.

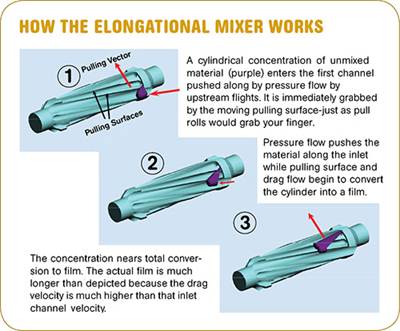

Read MoreStudy May Boost Prospects For Single-Screw ‘Elongator’

Dow Chemical Co., Midland, Mich., weighed in at last year鈥檚 SPE ANTEC with a paper discussing results of experiments they conducted on a novel elongational mixing device developed by Randcastle Extrusion Systems

Read MoreHere Comes the Sun...To FIlm Processing

Toray Plastics (America), Inc., last year completed the construction of a $2 million, 44-kW solar photovoltaic (PV) farm on its 70-acre campus in North Kingstown, R.I.

Read MoreOn Site: Where Art, Science, And Customer Focus Meet

Business strategy at Danafilms involves a mix of art and science in blending resins, designing layer structures, and operating flexibility for both short and long runs.

Read MoreAdd a Layer of COC to Boost Polyolefin Film Properties

As a discrete layer in coextruded polyolefin film, cyclic olefin copolymer provides higher modulus, greater heat resistance, improved thermoformability, and increased barrier

Read MoreNew Die Opens Up New Markets

General Plastic Extrusions Corp. found that out recently in converting a second-hand blown film line that had been used by its previous owner for R&D.

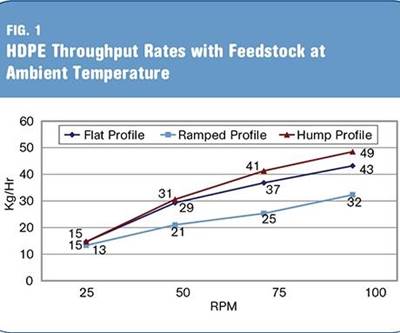

Read MoreWhy—and How—to Baseline Your Extruder

If you don’t baseline your extruder, then how are you going to set realistic expectations for its performance? Here's how to get going.

Read More