Why ‘Smart’ Blending May Be Right for You

Industry 4.0 smart controllers dial in the right recipes quickly with gain-in-weight blenders to eliminate material waste, cost overruns.

Are you still mixing color the old-fashioned way — and risking significant production cost overruns?

Despite advances in technology and Industry 4.0 data collection, some processors are still clinging to methods for blending resins that are surprisingly primitive. But make no mistake: The costs of inefficient material blending can skyrocket.

Failing to embrace precise, customizable blenders and controllers means missing out on thousands of dollars of cost savings. Gravimetric blending technologies allow operators to specify and track material usage by component.

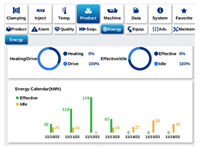

Cloud-based smart blending control setups enable manufacturers to view real-time process data and project future operational efficiency. Everything that happens to a plastic pellet once it enters a connected plant can be traced and evaluated — from blender to injection molding machine to scrap grinding. Infinite material types and locations can be tracked.

Many Scenarios for Success

Four scenarios demonstrate just a small number of the ways smart material blending controls can pay significant dividends:

- A beverage maker needs to put an additive in bottle caps. A smart blending control can gather process data over several weeks — enough to create an algorithm that properly dispenses the exact amount of additive required.

- A clothing maker is making bags with too much slip agent and can’t print on them. Using a smart controller to analyze process, the manufacturer can determine whether the slip agent is building up on the auger and eventually falling into the process.

- A processor is using too much of an expensive additive as well as too much virgin resin. A smart controller can determine if an operator is clearing inventory when starting a process over and not accounting for scrap rate. A smart controller can identify when the problem happens and who the operator is, and that operator can be scheduled to receive more training.

Failing to embrace precise, customizable blenders and controllers means missing out on thousands of dollars of cost savings.

- A processor must account for material use, process efficiency and/or employee performance. With data from smart blending controllers, companies can prove how much post-use material they are using, demonstrate the accuracy of the products they’re making or even track employee response time to material changes shift to shift.

Potentially High Cost of Material Waste

To be sure, smart controller adoption lags in the plastics industry. For instance, some production operations still employ someone who mixes resin and color by hand in a 55-gallon drum with a scoop or measuring cup. Still others might use a concrete mixer before wheeling the mixed material to the molding equipment. Such subjective blending methods invite not only material waste but bad parts — and more unnecessary production costs.

Then there are operations that employ more slightly advanced blending tools, such as a receiver with a remote proportioning valve or a digital doser (disk volumetric feeder). Some operations will pair these volumetric options with additional mixing ahead of the feed, trying to turn the material and homogenize it a bit. However, this method lacks the amount of residency time to ensure a consistently mixed batch. And even these methods don’t guarantee against material waste when blending for injection molding and extrusion processes.

Despite advances in technology over the years, many processing operations still use rudimentary methods to mix resin with additives. Source: ACS Group

How much potential waste are we talking about? Let’s assume an injection molder is running 500 pounds of parts an hour at 40 hours a week over 50 weeks with color pellet costing $2.50 a pound. If that molder’s target color consumption is 3%, using just 1% more color pellet equates to an overspend of $25,000 for the year for just one machine running an eight-hour shift. Multiply that by several more machines running two or three shifts each, and the potential surge in cost overruns from excess color consumption becomes apparent.

Gravimetric Blenders to the Rescue

This is where gravimetric blenders — particularly gain-in-weight versions — come in to save production errors and excess costs.

Gravimetric blenders enable to you track material consumption at a level not possible with volumetric approaches. Using a precision controller, the operator of a gain-in-weight blender can designate a recipe of two to eight virgin, regrind and color or additive components. The controller enables the operator to set the percentage of each material required, and the back end of the controller determines how much that percentage equates, too — for instance, how much of each material constitutes a two-pound batch. Each component is measured one at a time, with the batch gaining weight.

When full batch weight is achieved, hoppers open to discharge the material into the mixing chamber. Components will be blended, then dropped into the downstream process.

Current Blender Design Advantages

Blender paddle design and precision metering algorithms provide an added level of efficiency vital to a strong return on investment.

Paddle design is a key factor in blending precision and efficiency. A paddle that pulls material from all corners of the mixing chamber provides a more homogenous mix faster — up to one-quarter of the time of standard paddles — and delivers the most consistent batch-to-batch mixing. More consistent mixing means fewer part quality issues.

Paddle design is a key factor in blending precision and efficiency. A paddle that pulls material from all corners of the mixing chamber provides a more homogenous mix faster (up to one quarter of the time of standard paddles) and delivers the most consistent batch-to-batch mixing.

Meanwhile, a modern precision metering algorithm can improve batch-to-batch precision to accuracy of ±0.25%, with a span accuracy of the load cell down to ±0.2%.

Slide gate design also influences blender performance. An adjustable linkage, for instance, enables operators to limit the stroke of the gate — particularly important when molding minor components that require less than 1% of an additive. Coupled with an advanced fast processor control, as few as five pellets can be released per pulse. Precisely controlling the slide gate’s degree of retraction can dramatically limit material waste.

Collecting and Using Data

The next step in removing human error from the mixing process is precisely controlling mixing parameters. SCADA systems, which have existed since the late 1990s, are limited to telling operators what a blender has been used for previously and what current operation it is performing. They also required extensive integration work into a production platform.

However, contemporary mixing controllers incorporate Industry 4.0 tool capabilities that are invaluable in helping manufacturers gain uptime, especially by adding predictive maintenance capabilities. A tool built to integrate seamlessly into one’s production operation can begin to deliver blender usage data right out of the box through a hypersecure link.

Industry 4.0 technology seamlessly integrates mixing equipment to the cloud, giving users real-time process alerts and letting them view past data for insight into future operations and maintenance issues.

Not only are data-collecting Industry 4.0 mixing controls more secure, but the high-level metrics they collect lets users:

• Log material use

• Log blender use

• Compare target use vs. actual use

• Compare uptime vs. downtime

• Troubleshoot blender, material and process performance

Material usage is tracked in a customizable database that can track an infinite number of material types and locations. Operators can then assign those material types and locations to specific hoppers. Those values are stored in the database and can be viewed in real time.

With this level of detail, operators can monitor processes to an unprecedented degree. For instance, they can see how much polypropylene has been used across all blenders or set up an automatic report to run at specific time intervals to show where material came from. Operators can establish work zones to monitor multiple pieces of equipment — for instance, on an extruder line with three extruders and three blenders — and see how material that zone used at the end of the day.

By embracing next-level blending controls, manufacturers can track their true costs — down to every single pellet processed.

About the Authors: Mike Tuchalski Jr. is currently one of the two sales directors at ACS Group responsible for all sales activity in half of the U.S. and Canada. He has been with the company since 2017 and has operated in several roles throughout the company in his tenure. Tuchalski earned a bachelor’s degree with a double emphasis in marketing and finance from the University of Wisconsin-Green Bay. Contact: 262-777-0369; mtuchalski@acscorporate.com; .

Keith Packard is a seasoned control systems engineer with a degree in electrical engineering from Purdue University, graduating in 1994. With a career spanning over 30 years, he specializes in data analytics and processing, leveraging his technical expertise to design and optimize control systems across various industries. Known for a strong analytical approach, he is committed to solving complex challenges and driving innovation in the field. Contact: 270-843-4971; kpackard@acscorporate.com.

Related Content

Better Manufacturing Data Empowers Plastics Processors to Make Better Decisions

What’s needed to take all the data pulled from production planning, production monitoring and quality control systems and put it in the hands of the right people at the right time?

Read MoreDigital Manufacturing: Two Medical Molders Embrace Industry 4.0

‘Digitalization’ and ‘connectivity’ are loaded terms—shorthand for a whole new way of doing ´óÏó´«Ã½. It can’t be accomplished in one go. But two Midwest molders in the sensitive medical field are already feeling the benefits of their initial steps in that direction.

Read MoreSmart Granulator Control Integrates Size-Reduction Systems, Enables Predictive and Knife Maintenance

NPE 2024: Conair’s New SG Control is available for its Viper Granulators

Read MoreDigital Product Passport Trialed by Henkel Consumer Brands

Joint project between R Cycle and converter Korozo Group is implementing packaging traceability technology.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More