Extrusion

System Allows Fast, Efficient Die Cleaning

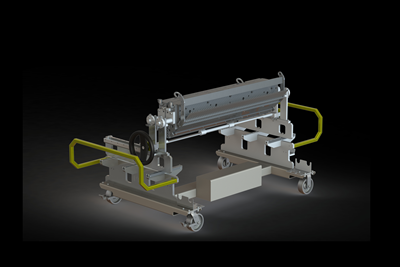

Processing Technologies International LLC (PTi) has developed a die splitting cart called uCAMS (Universal Cleaning Assembly and Maintenance System). The system was designed with the goals of flexibility, ease, and operator safety in regards to maintenance and upkeep of an extrusion die.

Read MoreNovel Line Produces 27-Microlayer Blown Film

Italian machine builder unveils blown film system that relies on feedblocks—far more common in flat-die processing—to yield thin yet strong film.

Read MorePregis Invests $80 million to Build New Film Plant in South Carolina

Plant will feature multiple state-of-the-art blown film lines and create 120 new jobs.

Read MoreFluff Feeder Offers Higher Film-Scrap Capacity, Better Reclaim Efficiency

Feeds granulated film scrap into a stream of virgin material and delivers the mix to extruder.

Read MoreJames Feeney, First President of W&H Corp., Dies

Long-time leader of W&H’s U.S. operations was 85.

Read MoreIn-Line Radar-Based Measurement of Extruded C900 PVC Pipe Reduces Material Cost, Improves Quality

New radar-based measurement technology enables processors to extrude higher-quality pipe with less material. With an automated closed-loop control system you’ll get more output and less scrap to significantly lower costs.

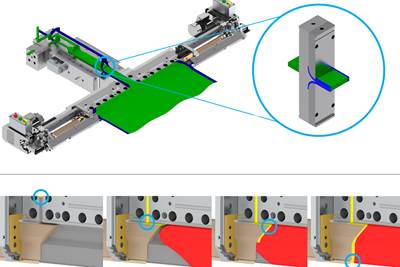

WatchEdge Encapsulation Boosts PLA Coating Speed

Technologies increases throughput, reduces coat weight in the extrusion coating of biopolymers by encapsulating the edges of the coating with LDPE.

Read MoreNew Screen Changer Lets Film Processor Ramp Up Scrap Usage

Retrofitting RSFgenius melt filter enables the German PE film processor Oldenburg to reprocess—rather than resell—production waste.

Read MoreHigh-Output PVC Pipe Head

Provides up to two times more output per comparable pipe size and has design features that allows for improved wall control while facilitating product changeover times.

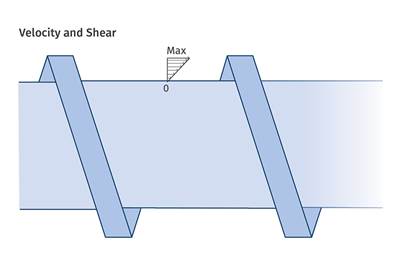

Read MoreUnderstanding the Influence of Screw Geometry on Melting Rate

They are not as closely connected as most processors think. Here’s why.

Read More