System Allows Fast, Efficient Die Cleaning

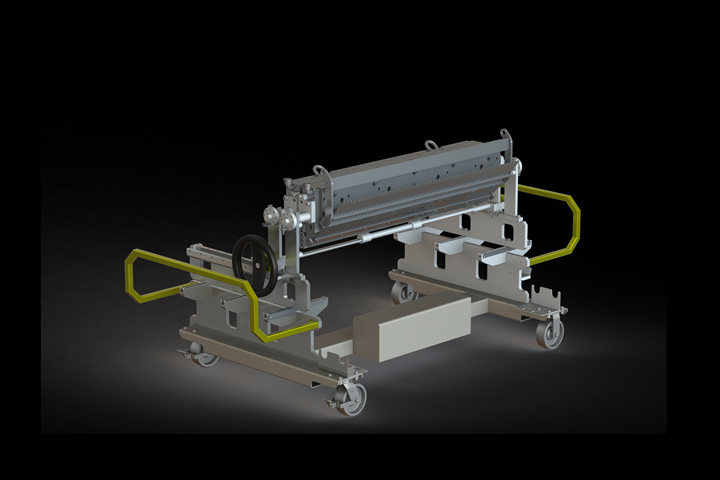

Processing Technologies International LLC (PTi) has developed a die splitting cart called uCAMS (Universal Cleaning Assembly and Maintenance System). The system was designed with the goals of flexibility, ease, and operator safety in regards to maintenance and upkeep of an extrusion die.

Processing Technologies International LLC (PTi) has developed a die splitting cart called uCAMS (Universal Cleaning Assembly and Maintenance System). The system was designed with the goals of flexibility, ease, and operator safety in regards to maintenance and upkeep of an extrusion die.

PTi says the uCAMS is foundational for any offline die maintenance program and is available in three configurations for the cleaning, inspection or repairs of single, dual or triple-manifold dies. The heavy-duty frame construction on casters provides mobility and accessibility so that maintenance can be performed in an environment and at a height that is adequate and safe for the operator.

In comparison to other die splitting carts on the market, PTi says uCAMS offers unique features that simplify the maintenance process. The first is its ability to accommodate variable die widths (39-79 in.) through the integration of adjustable trunnion supports. This versatility is said to beneift processors working with varied die widths, as it eliminates the need for multiple, width-specific carts or trunnions.

Secondly, the uCAMS is equipped with a single hand-wheel mechanism that requires only one person to perform the die splitting procedure. Upon manual rotation of the wheel, and within a matter of seconds, the die is separated into respective components which are then capable of turning 360° for even greater access to the die surfaces.

Lastly, for those instituting SMED protocols for LEAN production, the onboard tool box further enhances workflow efficiency by having all the necessary equipment and tools readily available.

Related Content

-

Auto-Profile System for Blown Film Rotating Dies

NPE2024: New technology can slash gauge variation by 50%.

-

Novel Air Ring Solves Gauge Variations for Film Processor

Crayex installs Addex gauge-controlling air ring built for rotating/oscillating dies on a problematic line and notices dramatic improvement in thickness variations.

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.