Mack Prototype Expands Additive Manufacturing Capabilities

The Massachusetts-based wholly owned subsidiary of Mack Molding Co. has added a Stratasys F770 machine capable of producing large 3D-printed parts.

Mack Prototype (Gardner, Mass.), a division of Mack Molding that is focused on complex prototyping and low-volume manufacturing, has installed a Stratasys F770 Fused Deposition Modeling (FDM) printer capable of producing large 3D printed parts.

Running both ABS and ASA materials, the F770 features the widest build chamber of any Stratasys FDM 3D printer, with a build envelope that spans 39 by 24 by 24 in. That is 13-cubic feet of build volume allowing it to produce large, single parts or large assortments of smaller parts.

Typical part accuracy is ± .010 in. (.254 mm) or ± .002 in./in. (.050 mm/mm), whichever is greater. In a release, Mack Prototype President Greg Cebular said the new machine will allow the company to print large parts as a single piece without having to join separate components together. Potential applications for the new machine range from large prototypes to large master patterns that are used in cast urethane molding, as well as low-volume batch runs of parts of various sizes.

In the last 18 months, Mack Prototype has invested more than $875,000 in equipment and infrastructure. In addition to the Stratasys, the company’s fleet includes a smaller format FDM printer, along with Carbon CLIP Digital Light Synthesis (DLS), HP Multi Jet Fusion (MJF) and Formlabs Stereolithography (SLA) machines.

“From just a few parts to as many as a few thousand, our team of engineers can help customers with their low-volume and bridge production requirements with flexible solutions designed to deliver high-quality parts while reducing time and cost,” Cebular said in the release, noting that if production needs change, Mack can help its customers meet higher volume demand with traditional tooling and molding, scaling production at Mack Prototype or at one of Mack’s manufacturing centers.

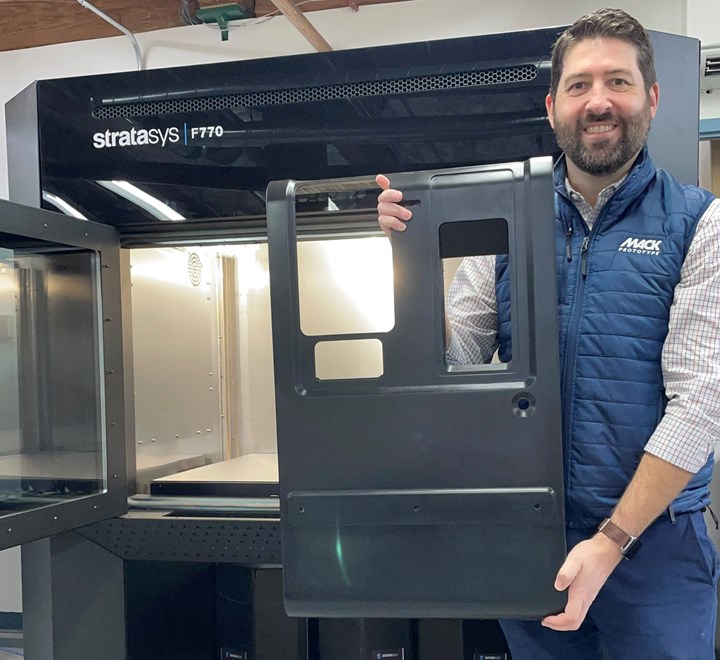

Mack Prototype President Greg Cebular shows off a large part from the company’s new Stratasys F770 3D Printer.

Photo Credit: Mack Prototype

Related Content

-

Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

-

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

-

5 Trends in 3D Printed Injection Mold Tooling

3D printing has moved beyond conformal cooling, and is now being applied to injection molds more broadly. Observations on additively manufactured mold tooling from the Plastics Technology Expo — PTXPO 2025.