Matthew Naitove Contributing Editor

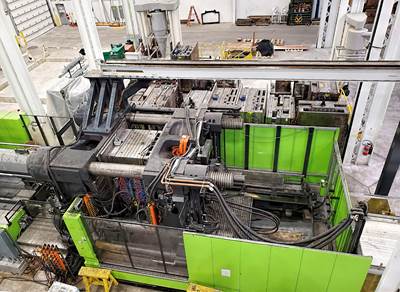

More Milestones for EVCO Plastics

Custom injection molder is adding floorspace, machine capacity, and contract manufacturing capabilities at multiple plants in the U.S. and Mexico.

Read MoreContinuous Compression Molding Goes Multilayer

SACMI’s CCM system now can mold multilayer barrier containers such as coffee pods.

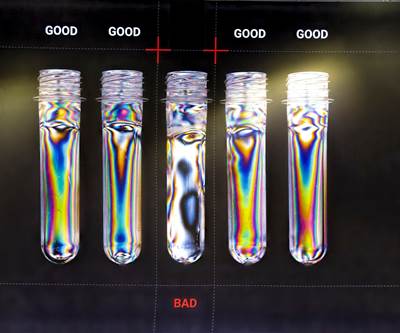

Read MoreBlow Molding: Online PET Preform Inspection Uses AI to ‘Self-Learn’

SACMI’s new Preform Vision System can be used inline with PET preform injection molding.

Read MoreInjection Molding: Magnetized Elevation Pads Simplify Support of Molds & Machinery

Rhino Feet from Molders Choice support up to 7000 lb and have a molded-in magnet to stick to ferrous surfaces.

Read MoreInjection Molding: Largest Wittmann Robot Yet Handles 100 kg

French molder uses its 3-m demolding stroke and large payload capacity to mold waste bins.

Read MoreInjection Molding: Check Ring Resists Corrosive Flame-Retardant Additives

Zeiger Industries’ new nonreturn valve lasts 85 times longer in molding test with nonhalogen flame retardant.

Read MoreNew North American Office & New Presses for Bole Machinery

Bole America in Stow, Ohio, offers new models of two-platen and servohydraulic toggle presses.

Read MoreInduction Heating Offers Potential in Auto Lighting

Superior replication of complex mold textures helps optimize the light path in molded lenses.

Read MorePaper IML Trims PP Tub to a Skeleton

Stiff paper in-mold label provides topload strength while allowing removal of 76% of the PP in injection molded food tubs.

Read MoreInjection Molding: Faster, Smarter, More Efficient Machines Tackle Sustainable Molding at K 2019

Blazing speed plus shrinking energy consumption supported the “green” theme at the big show. Smarter controls and growing connectivity were another key focus.

Read MoreBlow Molding: Something for Everyone at K Show

Packaging, industrial, continuous-extrusion, accumulator-head, injection-blow, stretch-blow, EPET, foam, sandwich co-injection—the blow molding news was wide ranging at K 2019.

Read MoreBekum America Is Expanding

A 40% expansion in Michigan is expected to be completed later this year.

Read More