Matthew Naitove Contributing Editor

Coronavirus Doubles Demand for Used Blow Molding Machines

Demand for hand sanitizer, alcohol, cleaning products and beverages is reportedly straining capacity in blow molding.

Read MoreMolder Pushes Limits of Rapid Tooling in Coronavirus Crash Projects

Harbec explores 3D printed aluminum molds with conformal cooling.

Read MoreEVCO Plastics Gears Up To Mold Coronavirus Test Kits

The firm has added shifts, reassigned people and injection machines—and is buying new ones—in a crash program to mold and assemble COVID-19 test kits.

Read MoreFast, Simple, Low-Cost Method Unveils ‘True’ Melt Temperature

Long a mystery to injection molders, actual temperature of melt entering the mold is said to be revealed by an easy procedure that is repeatable and takes less than a minute.

Read MoreHow Graham Packaging Counters PCR Supply/Demand Squeeze

Customers want more PCR—including food grade—than recyclers can supply. Solutions involve efforts to educate customers, employees, and the community at large. New technologies also offer hope.

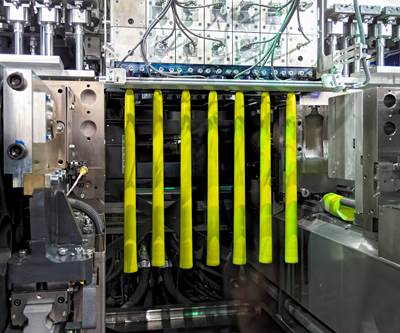

Read MoreInjection Pairs with Blow Molding for In-Mold Assembly

At Sussex IM, compact cells of side-by-side injection and blow molding machines “assemble” reusable water bottles with insert blow molding and automated transfer, trimming and leak testing.

Read MoreReopening America: Winnebago Industries Goes Back to Work

Plants in five states have reopened, after a variety of measures taken to support employees, customers and communities.

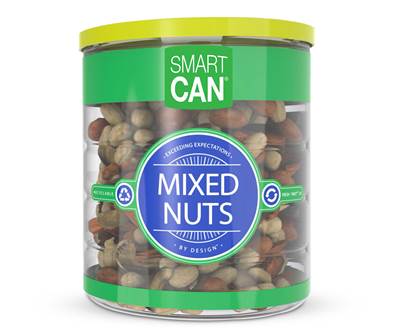

Read More100% Recyclable PET Vies to Replace Composite Cans

Ring Container Technologies, Oakland, Tenn., a blow molder of HDPE and PET packaging, announced the first customer for its new SmartCAN, a PET can designed to replace the common composite can with a much more easily recyclable alternative at comparable cost.

Read MorePlasma “Glass” Barrier Coating Developed for Reusable PET Bottles

IKV and KHS Corpoplast in Germany collaborate on SiOx barrier coating that can withstand caustic washing for multi-trip PET bottles.

Read MoreCoronavirus Emergency: Ventilator Valves 3D Printed at Hospital

Valves in short supply made in hours with FDM and SLS printers. New heat-resistant material shows promise.

Read MoreTooling: Heat-Resistant 3D Printing Material Suited to Plastic Tooling

A tough, heat-resistant resin for 3D printing was introduced last November by 3D Systems.

Read MoreThermoformed Detergent Tub Now Contains 50% Recycled PP

Tub sits inside a recycled cardboard wrapper that permits a 40% reduction in the overall weight of plastic.

Read More