.jpg;maxWidth=250;quality=70)

Jim Frankland President

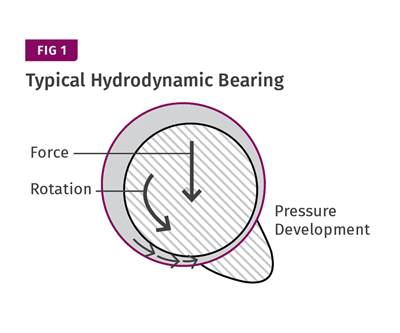

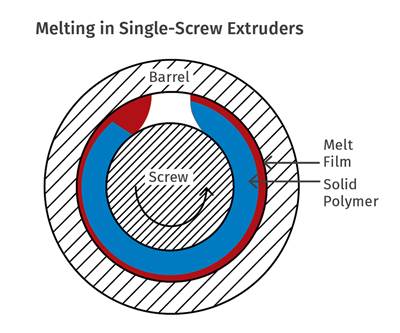

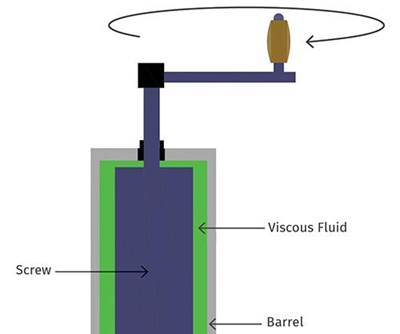

How ‘Hydro Wedges’ Reduce Screw Wear

Using them only in the melting section provides for greater design freedom and negates the impact these devices can have on output and melt temperature.

Read MoreExtruding with Fillers

You can use the reference point from processing unfilled polymer to determine whether you can run filled resin on your current system.

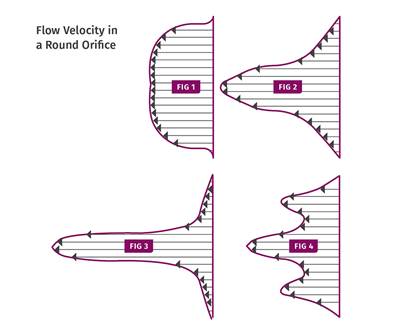

Read MoreDon’t Build In Melt-Temperature Variations

It’s not unusual for polymer to exit the extruder with a uniform melt temperature, only to be fouled up by downstream flow pipes and the like. Here’s how to avoid this.

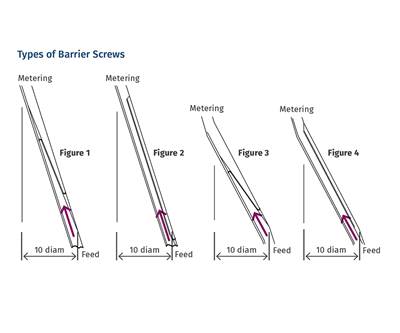

Read MoreWhich Barrier Screw for You?

It depends ... mostly on the melting requirements of the polymer.

Read MoreWhat Output Can I Expect?

Processors ask screw designers this question a lot. But neither output nor melt temperature can be predicted without details on the polymer and head pressure.

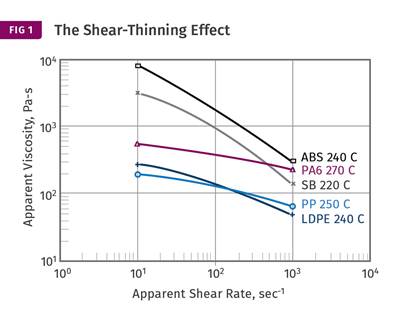

Read MoreExtruding Very High-Flow Polymers

Screw designs not suited to process lower-viscosity materials will result in poor melt quality and lower outputs.

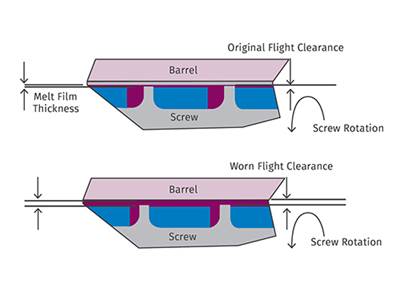

Read MoreDo You Have Screw Wear?

It’s generally caused by metal-to-metal contact, and your first indicator will be poor melt quality.

Read MoreEXTRUSION: Is Head Pressure Sapping Your Extruder’s Strength?

A redesign of all of the flow paths between the end of the barrel and die may be in order.

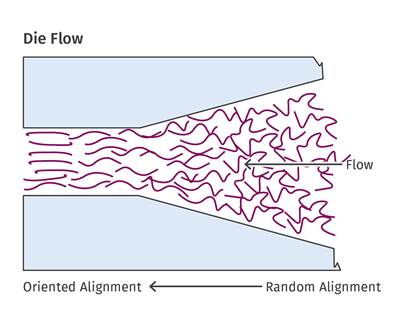

Read MoreEXTRUSION: Orientation: The Good and the Bad

Depending on what you are trying to accomplish, molecular orientation can have a positive or negative impact on your part. Here’s how to control it.

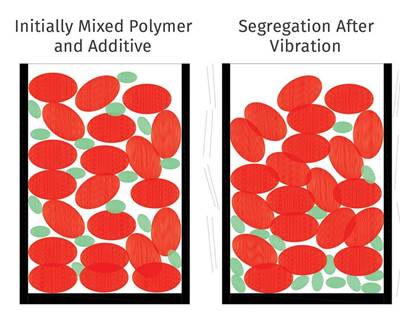

Read MoreEXTRUSION: Better Mix In Means Better Mix Out

Segregation or de-mixing of polymers and additives can be a big problem in single-screw extrusion. Here’s why it happens, and how to fix it.

Read MoreEXTRUSION: How Slow Can You Go?

Larger screws designed for high outputs will generate a variety of problems if run too slowly. Here’s why.

Read MoreEXTRUSION: Finding the Sweet Spot in Screw Design

The compression ratio of a screw does not provide enough detail on how it will perform. Screw design is a balancing act that takes many variables into account.

Read More