.jpg;maxWidth=250;quality=70)

Jim Frankland President

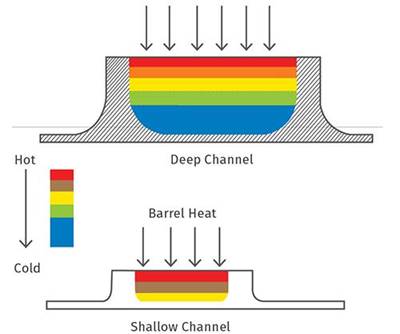

The Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

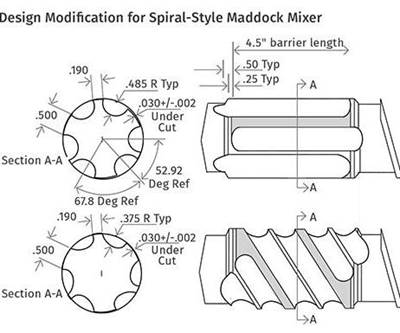

Read MoreEXTRUSION: Understanding The Barrier Gap

All barrier screws are not created equal, and the barrier length and gap can be one of the reasons.

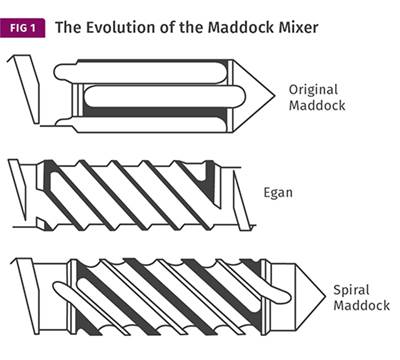

Read MoreEXTRUSION: Venerable Maddock Mixer Still an Extrusion Workhorse

Variations to this decades-old mixing section are widely used, but processors should carefully analyze these designs and not assume they will perform better.

Read MoreEXTRUSION: Managing Regrind

Reusing scrap is a necessary evil. But be aware of the negative impact scrap has on properties and extrusion efficiencies. Start by developing a regrind-usage program.

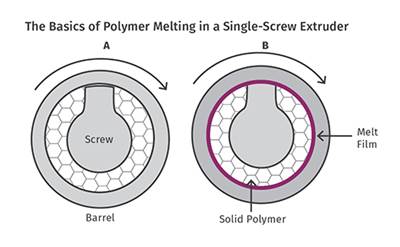

Read MoreEXTRUSION: Melting 101

Learn the basics on how polymer melts in a single screw. Barrel temperature plays less of a role than you might think.

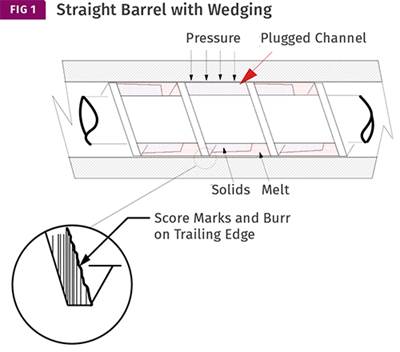

Read MoreEXTRUSION: The Two Main Causes of Screw Wear

Wedging and misalignment are often confused with each other when inspecting a worn screw.

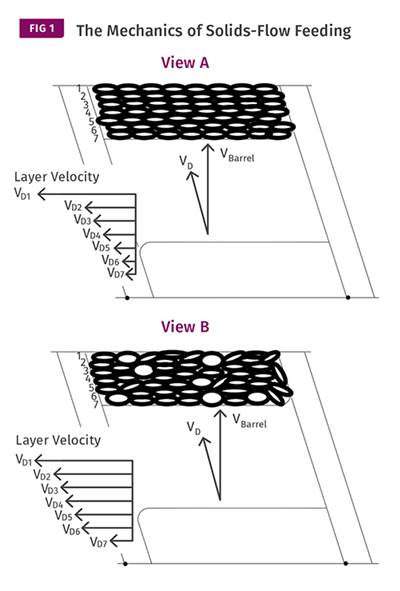

Read MoreEXTRUSION: Pellet Geometry Can Impact Output

A simple angle-of-repose experiment can help you determine how your pellets will feed.

Read MoreEXTRUSION: Barrier Screws and Mixers

For some reason, there are a lot of barrier screws in operation with high-shear mixers, when a distributive mixer is usually a better choice.

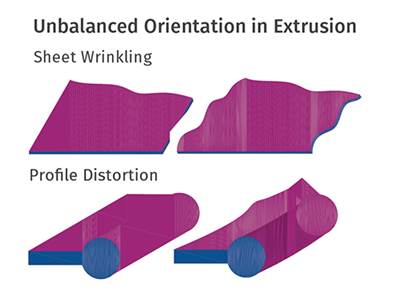

Read MoreExtrusion: How to Adjust for Polymer Shrinkage and Orientation

Polymers shrink and orient. Sometimes orientation is unbalanced, resulting in misshaped parts. But there are steps beyond tweaking the die that can mitigate these effects.

Read MoreEXTRUSION: Another Technique for Controlling Melt Temperature

Flight widths are almost always designed at 10% of the screw diameter. But they can be optimized to reduce melt temperature and perhaps boost output.

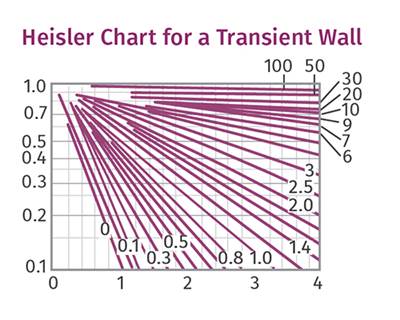

Read MoreEXTRUSION: Cooling: The Critical Function in Extrusion

Figuring out how much cooling your process needs is complicated. But there are ways to approximate.

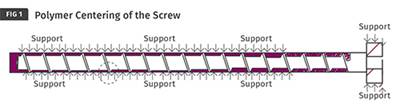

Read MoreEXTRUSION: Here’s Why You Shouldn’t Run Your Extruders Dry

At least not for longer than a few minutes. The thin film that’s captured between the screw flights and barrel wall supports the screw and acts as a lubricant. Without it, galling can occur.

Read More