.jpg;maxWidth=250;quality=70)

Jim Frankland President

What You Need to Know About Roll-Cooling Design

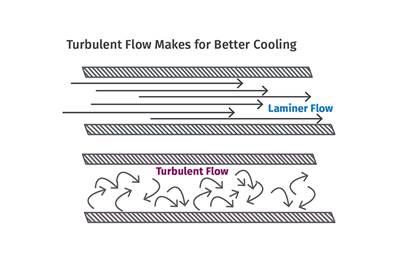

Cooling rolls might not look like high-tech machines, but the fact is there is a surprising amount of technology involved in their design, manufacture and use. Here’s what you need to know.

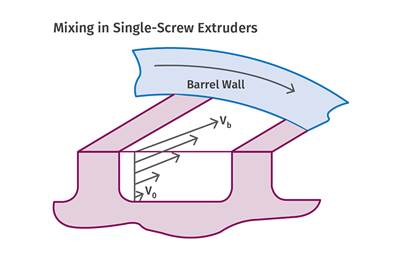

Read MoreA Guide to Single-Screw Mixers

To design the best mixers for single screws, you must completely understand how polymer moves through a mixer channel or groove.

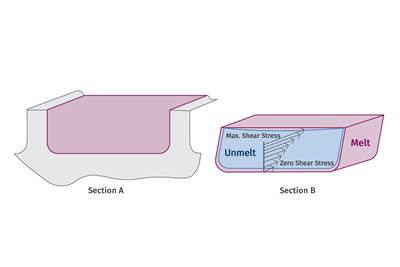

Read MoreThe Role Barrel Temperatures Play in Melting

You need to understand the basics of how plastic melts in an extruder to properly set your process and troubleshoot any issues. Hint: it’s not about the barrel temperature settings.

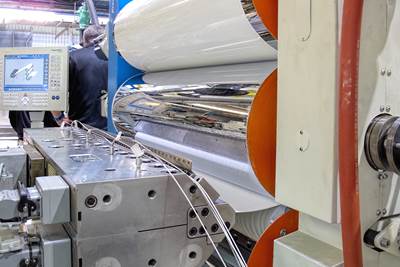

Read MoreMaximize the Cooling Capacity of Your Extrusion Line

Maximizing output in extrusion requires a thorough understanding of not only the cooling requirements of the extruder but of the extrudate as well.

Read MoreStop Shopping for a 'Jack of All Trades' Extruder

Some processors try to find “fits all” extruders to cover all processing possibilities. But you’d have to grossly overpower it to achieve this, and that’s expensive up front and will result in inefficiencies over time.

Read MoreSingle vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read MoreRoll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreLooking to Run PCR on a Single Screw? Here’s What to Keep in Mind

Just drop it in and mix it up? Sorry, there’s a lot more to it than that. Here is some of what you need to consider.

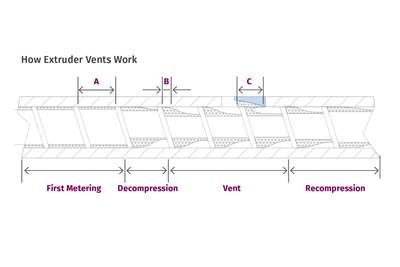

Read MoreThe Right Way to Design Vents in Single-Screw Extruders

Designing vents for single-screw extruders requires understanding of polymer flow in the screw channels. Some designs are more effective than others. Here are some guidelines.

Read MoreWhy Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

Read MoreTake Proper Care in Feeding Your Extruder

Everything that happens in an extruder starts at the feed throat, so proper attention to that zone’s temperature pays off in quality and productivity.

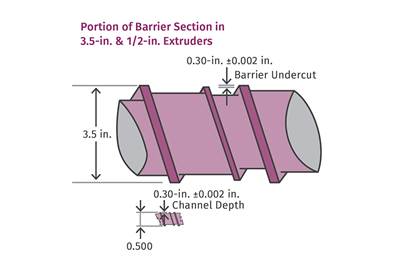

Read MoreSmaller Screws Impose Bigger Challenges

Very small extruder screws work just about like their larger cousins, but some critical differences make them harder to design and machine.

Read More