Tooling Know-How

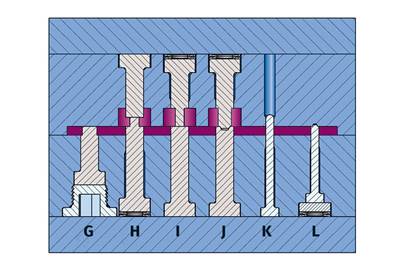

How to Form a Hole with a Core Pin: Part 2

Prevent wear, flash, and mold damage with these design methods.

Read MoreHow to Form a Hole with a Core Pin: Part 1

Prevent wear, flash, and mold damage with these design tips.

Read More80 Questions Moldmakers Should Ask Themselves … and Their Customers

If you’re a molder or brand owner/OEM, be ready to supply the answers before the program is launched.

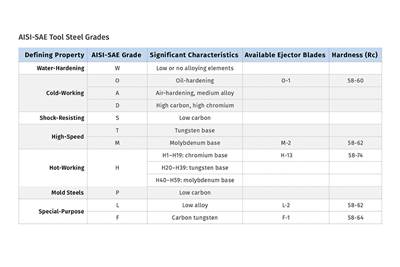

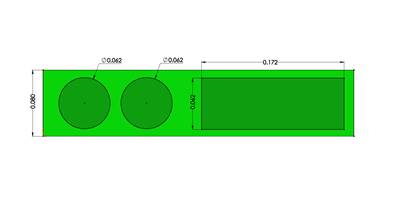

Read MoreWhat You Need to Know About Blade Ejectors: Part 3

Follow these guidelines to prevent premature wear, flash and galling. The focus here is on corner radii.

Read MoreWhat You Need to Know About Blade Ejectors: Part 2

Follow these guidelines to prevent premature wear, flash and galling.

Read MoreWhat You Need to Know About Blade Ejectors: Part 1

Follow these guidelines to prevent premature wear, flash and galling.

Read MoreGet Better at Quoting Injection Molded Parts: Part 4 of 4

This fourth and final installment focuses on labor, packaging, secondary operations and various assorted details.

Read MoreGet Better at Quoting Injection Molded Parts: Part 3

Follow these detailed tips to get the jobs you want. This installment focuses on the mold and the molding machine.

Read MoreGet Better at Quoting Injection Molded Parts: Part 2

Follow these detailed tips to get you the injection molding jobs you want. Here we factor in the costs of scrap and regrind, along with energy and certain additives.

Read MoreGet Better at Quoting Injection Molded Parts: Part 1

Follow these detailed tips to get you the jobs you want. This installment focuses on the various raw material aspects of quoting.

Read More