Stretch Blow Molding

NPE Newsfinder: Blow Molding

Examples of the growing trend toward all-electric blow molding machines for packaging will either be physically present or shown in videos and brochures at NPE.

Read MoreInjection Molding Troubleshooter: Get the Most from Flow Simulation

Flow-simulation software is one of the most powerful tools ever developed for improving injection molded part quality.

Read More3D Blow Molding Gains Momentum

Although this continent has been slow to follow Europe’s example, market forces in North America are finally shifting in favor of three-dimensional blow molding.

Read MoreGarbage In, Good Plastics Out

Experts consider it the most high-tech recycling plant in the world: Schwarzataler Kunststoff in Germany takes dirty bottles and film from post-consumer recycling and turns them into automotive and other compounds in a fully automated process.

Read MoreNew Polypropylene Families for Packaging, Blends & Composites

Two new lines of polypropylene resins from Basell North America challenge PS, PET, PVC, and other PPs for clear, rigid packaging.

Read MoreAll-Plastic Paint Cans Challenge Steel

After considerable success in Europe, all-plastic gallon paint cans are spilling into North America’s retail paint market more quickly than was anticipated just a few months ago.

Read MoreNPE News Wrap-Up: Blow Molding

Long-stroke machines go rotary, all-electrics grow larger,and PET bottles get a new “glass” coating. Visitors to the show got to see all these and more.

Read MoreBlow Molding - Higher Output Vies With Flexibility

The emphasis in blow molding equipment introductions at NPE 2003 is on higher output capability and greater versatility to take on emerging markets.

Read MoreAll-Electrics & Stretch-Blow Get Top Billing

Energy efficiency and production cost savings were dominant themes of the blow molding exhibits at K 2001. A handful of new all-electric machines aroused intense interest, though they are aimed primarily at niche markets. And in two-stage (reheat) PET stretch-blow molding, the focus was on boosting output per cavity.

Read MoreBlow Molding Gets Green Light in Detroit

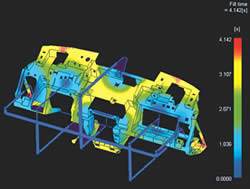

Technical blow molding is changing the contours of automotive interior trim, load-bearing floors, seat-back systems, and under-hood ducting. Favorable economics, process refinements, and the emergence of tailored materials and equipment are taking the brakes off blow molding's earlier limits, and pointing a way to cost cutting.

Read More