Stretch Blow Molding

Developing Tomorrow’s Containers: Inside Amcor’s R&D Center

How award-winning package design, full-service laboratory facilities, and game-changing process development support a world-class injection and blow molder.

Read MoreBLOW MOLDING AT NPE: Energy Savings, Lightweighting & Flexibility

New machines are mostly all-electric, hybrid, or servo-hydraulic.

Read MoreBLOW MOLDING: Single- or Two-Stage PET Bottle Making: Get to Know Your Options

The decision which process to use can be quite complex. Here are pointers that will help you to choose the right one for your application

Read MoreMachinery Innovator Dewey Rainville Dies at 91

Developed numerous technologies in blow molding; involved in start-ups of leading auxiliary equipment firms.

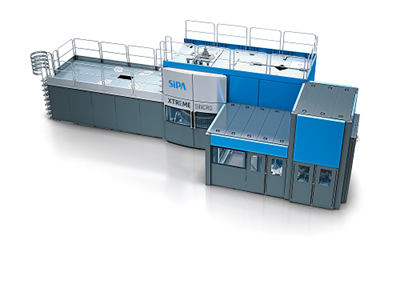

Read MoreSIPA Acquires Automa PET Bottle Machine Line

SIPA adds rotary single-stage machines to its arsenal.

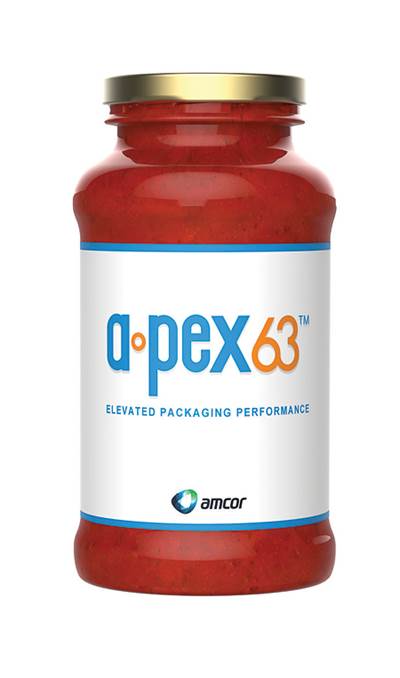

Read MoreFirst Hot-Fill PET Jar With Metal Lug Closure

Amcor wins the race to give PET pasta-sauce jars that satisfying "pop" on opening.

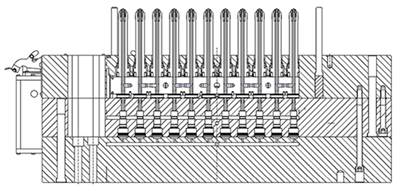

Read MoreNew in PET: Injection-Compression-Stretch-Blow Molding

Continuous, rotary injection-compression molding of preforms is linked to rotary stretch-blow molding.

Read MoreAmcor Wins Race for Hot-Fill PET with Metal Lug Closure

Consumers get the reassuring "pop" of freshness without the weight and fragility of glass.

Read MoreHow to Address Uneven Wall Thickness in Stretch-Blow Molding

Many conditions must be met to get the best wall distribution in a PET bottle. Skilled operators are, as always, indispensable.

Read More