Resin Conveying

HOW TO COMPARE DRYERS? A Complex Challenge With No Simple Answers

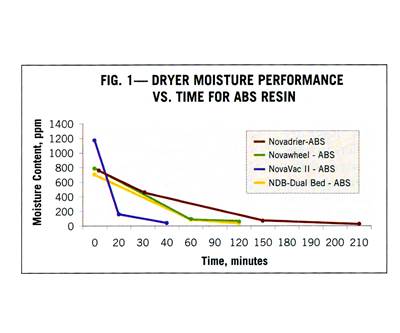

Is one type of resin dryer faster or more energy-efficient than another? That question prompts competing claims from suppliers—but very little concrete data. When one vendor performed controlled tests to get some answers, its results, published here for the first time, prompted further debate about the difficulties of making valid comparisons and the many complex issues involved in dryer selection.

Read MoreTherapy for 'Over-Weight' Weigh-Hopper Scales

Scale performance inaccuracies are typically false-positive weights where the scale reads more material than it is actually receiving. There are steps to manage mechanical scale issues.

Read MoreColoring on the Machine: You Can Do It Right

Coloring at the machine can offer significant cost benefits, including lower material inventory costs and improved process flexibility when compared with the cost of buying precolored resin or installing a large-capacity central blender to premix resin and color concentrate.

Read MoreExtruding Biopolymers: Packaging Reaps Cost Benefit of Going 'Green'

Plastics made from renewable carbon chains, not fossil carbon from oil or gas, are suddenly a solid commercial reality. The draw isn’t just “green” marketing, but the “green” of stable prices not linked to petrochemicals.

Read MoreNPE 2006 News Wrap-Up: Materials Handling: A Host of Refinements and Updates

NPE 2006 held no revolutionary changes in dryers, blenders, feeders, loaders, or conveying controls, but widely adopted improvements make the newest models easier to use and maintain—and easier on the budget, too.

Read MoreWhat to See at NPE 2006: Materials and Parts Handling

Dryers, feeders, blenders, loaders, metal detectors, level sensors, mechanical and pneumatic conveyors, silos, bins, pumps, filters, valves, box fillers, bag dumpers, and materials-handling control systems constitute one of the biggest categories of products on display at NPE.

Read MoreNPE 2006 News Flash

Injection MoldingSimplified Hot Runners Save Time & CostA new lower-cost hot-runner alternative to valve gating is suited to less critical cosmetic applications where users need predictable and reliable gate opening but not sequential gate operation.

Read MoreAll-Electric Plant Gets World-Class Results

In mid-2004, Delphi Connection Systems, part of Tier 1 automotive supplier Delphi Corp.’s Packard Electric operations, flipped the switch on a new 190,000-sq-ft, $58-million plant in Vienna Township, Ohio.

Read MoreHow to Get a Handle on Materials-Handling Problems

The best way to avoid materials-handling problems is to design and install the system properly in the beginning.

Read MoreMaterial Handling and Drying Are a Molder's 'Central' Issue

The benefits of centralized material handling have been demonstrated for decades, yet somehow the message continues to come slowly to mid-size processors like Jackson Products Inc of St.

Read More