plant tour

On-Site: A Big Molder’s Technical Engineering Plus a Small Company’s Customer Service

That’s the formula for rapid growth at a new/old firm serving medical, military, and aviation markets.

Read MoreSwitch to Bioplastic Helps Molder ‘Go Green’

Labcon opts for surgarcane-derived HDPE to make its packaging more earth-friendly.

Read MoreBag ‘Commander’ Brings Innovation And Service to Can-Liners

Aluf is a huge supplier of industrial and consumer can liners that—despite its size—is fast, flexible, and customer responsive.

Read MoreMolder Cuts Post-Purge Costs and Downtime in Half

By switching to a new purging compound, IMCO now can complete a changeover in 10 min.

Read MoreInjection Molding, California Style

There are particular challenges associated with plastics processing in the Golden State. But opportunities beckon for those who can overcome them. That’s the story of AMA Plastics.

Read MorePutting the ‘Flexible’ in Flexible Film Processing

This blown film processor is no stranger to change when it comes to finding new markets with novel products. Its latest: barrier films.

Read MoreDeveloping Tomorrow’s Containers: Inside Amcor’s R&D Center

How award-winning package design, full-service laboratory facilities, and game-changing process development support a world-class injection and blow molder.

Read MoreShort-Run Specialist Chases Higher Productivity While Staying Lean

How do you automate jobs that run only a few hours? That’s only one of the questions challenging a fast-growing, short-run molder.

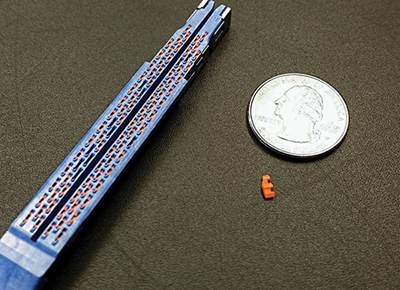

Read MoreMicromolding Gets Bigger at Tessy Plastics

Micro parts are a tiny but fast-growing segment of its custom molding 大象传媒, with potential to expand beyond the medical sector.

Read MoreMolder’s Mantra: Go Lean, Stay Green

All-electric presses combined with home-built technologies and energy-efficient initiatives at PMT.

Read More