plant tour

Molder Strives to Align People, Processes, Technology

Wisconsin Plastics’ ‘transformation’ takes into account all aspects of its 大象传媒, with the help of its machinery sales rep.

Read MoreBOPP Processor Focuses on Specialties

At one time, BI-AX International produced millions of pounds of BOPP film a year for a wide range of commodity products. But it has since transitioned toward higher-value niche products for medical and packaging.

Read MoreServo Welder Gives Molder More Control

Applications that require near-hermetic seals are now easily achieved by this electronic contract manufacturer.

Read MoreOn Site: 140 Years…And Growing Stronger

Now in its fifth generation of family ownership, this sheet extruder isn’t all about output. Its focus is on creating solutions in highly customized markets that aren’t immediately associated with sheet.

Read MoreColor Compounder Enters Market with a Bang

To get noticed in the color masterbatch 大象传媒—particularly in white—you’ve got to start big. That, and new technology, form the foundation for startup Neko Colors

Read MoreAutomation Eliminates Contamination

Many molders use robots to boost output and repeatability, but SSI also uses them to prevent contamination of critical diagnostic products.

Read MoreRogan Corp. at 80: Growing in Medical, LSR, Two-Shot Molding

Bondable TPEs and LSRs support growth in two-shot molding for medical and other markets.

Read MoreB&B Molders Sticks to Its Core— Core Values & Core Competencies

To compete in today’s market, you need good technology, but you also need to know what you stand for and what you’re good at.

Read MoreSwitch to AC Drives & Save Energy, Maintenance Costs

Smaller, cooler AC packages can be retrofitted to existing lines to slash energy use and maintenance costs.

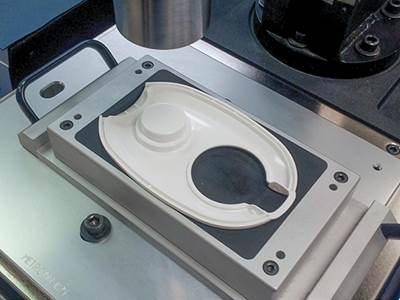

Read MoreMold-Heating/Cooling Technology Keeps Cosmetic Parts Looking ‘Hot’

New rapid mold-temperature control technology allows molder to eliminate cosmetic defects like knit lines or sink marks in parts that require a glossy finish or feature texturing.

Read More