Mold Maintenance

Avoid Scale Buildup: The Silent Enemy of Cooling Performance

Obstructions in cooling can wreak havoc on molding. Here, a well-known supplier to molders that also molds recounts its experience and offers tips on how you can keep things flowing.

Read MoreThe Five “Ms” of Molding—Part II: The Mold

A bad mold can cripple a process; learn what areas should be considered as a tool is evaluated and reviewed.

Read MoreSo How Fast Can You Change a Mold?

A contest next month at a U.K. trade show will crown one molder king of the quick-change artists.

Read MoreTool Time at Molding 2016

Plastics might replace metals in various applications, but in injection molding those parts require steel-based tools to be created, putting molds, and metal, at the center of the process.

Read MoreTOOLING: Repairing Molds in the Press: Part 3

This is the final part of a series on tooling in the press. This column will cover repairs that can be accomplished in the press.

Read MoreTOOLING: Designing Molds for Easy Cleaning & Maintenance in the Press

Pay attention to water leaks and rust, proper grease selection, vent buildup, and checks for wear.

Read MoreTOOLING: Designing Molds for Easy Maintenance in the Press, Part 1

Attention to design of cooling, ejection, and slides can save downtime and maintenance headaches.

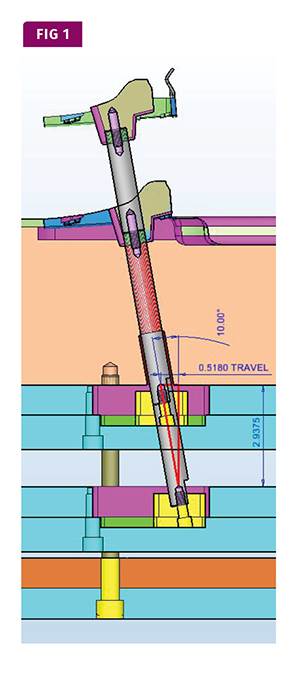

Read MoreTOOLING: Having Trouble with Lifters?

Lifters can cause tool maintenance, repair, and processing issues if not designed properly. Here we begin a series on how to avoid all this.

Read MoreMold Maintenance Hand Skills: It’s All about Connectivity

It takes a blend of brawn and brains for any tradesman or repair technician to become a craftsman or journeyman. And these skills can be learned.

Read More